In hydraulic machinery, one of the most frustrating issues operators face is when the system pressure gauge shows normal values, but the cylinder still delivers insufficient push force. This not only slows down production efficiency but also risks damage to both the cylinder and connected equipment.

In this article, we’ll explore the main reasons why hydraulic cylinders lose pushing power, and provide practical solutions for troubleshooting.

One of the most common and frustrating issues operators face is when the system pressure gauge shows normal values, yet the cylinder fails to deliver the expected push force. This phenomenon not only reduces productivity but also risks costly downtime and component damage.

In this article, we’ll dive deep into:

The mechanism behind cylinder thrust generation,

The main reasons for insufficient push force,

A step-by-step troubleshooting process, and

How professional cylinder design and manufacturing can prevent such failures.

1. Why System Pressure ≠ Cylinder Push Force

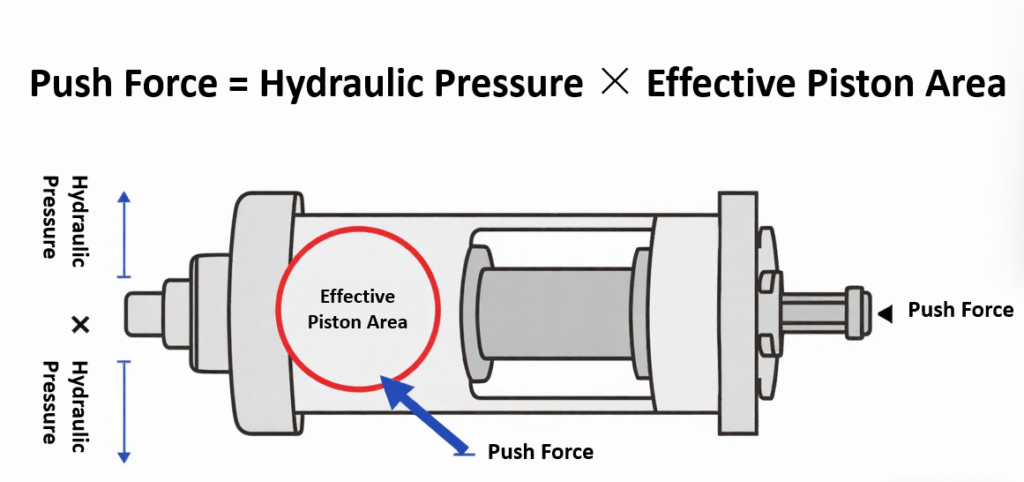

It is a common misconception that a normal pressure reading guarantees sufficient thrust. In fact, cylinder output depends on two factors:

Push Force = Hydraulic Pressure × Effective Piston Area

If either factor is compromised—whether due to leakage, resistance, or incorrect measurements—the cylinder’s push force will not match its theoretical value.

👉 This means that a system can appear healthy while still suffering from hidden efficiency losses.

2. Major Causes of Insufficient Cylinder Push Force

2.1 Internal Leakage – The Silent Efficiency Killer

Cylinder barrel or piston wear: Scratches, ovality, or clearance beyond tolerance reduces sealing effectiveness.

Damaged piston or rod seals: Leads to pressure loss between chambers.

Valve block leakage: Worn valve spools, defective hydraulic locks, or faulty relief valves can bypass pressure internally.

👉 Internal leakage can reduce thrust by 20–40% before being detected, making it a leading cause of hidden performance loss.

2.2 Mechanical Resistance – Extra Load on the Cylinder

Installation misalignment: Even a 0.1° deviation can significantly increase side loads.

Overtightened or poorly lubricated guide components: Raises friction, wasting valuable thrust.

Mechanical interference or deformation: Blockages in actuators or load structures restrict movement.

👉 According to field studies, improper installation accounts for nearly 30% of cylinder performance complaints.

2.3 Pressure Measurement Errors – Misleading Readings

Pressure gauges installed too far from the cylinder inlet may not reflect actual working pressure.

Incorrect regulator or valve settings cause real pressure to be lower than displayed.

Outdated or damaged gauges give false confidence.

👉 Always confirm pressure at the cylinder port with a calibrated instrument.

2.4 Seal System Failures – Shortened Service Life

Wrong seal selection for oil type or temperature conditions.

Improper installation leading to twisting or extrusion.

Oil contamination above NAS 9, which accelerates wear and shortens seal lifespan.

👉 High-quality seals can extend cylinder life by 30–50%, while poor seals lead to recurring failures.

2.5 Excessive Oil Return Backpressure – Hidden Energy Loss

Clogged return filters increasing resistance.

Undersized or bent piping creating flow throttling.

Reversing valve with insufficient flow capacity causing return line pressure buildup.

👉 Backpressure higher than 0.3 MPa can dramatically reduce cylinder efficiency.

3. Professional Troubleshooting Process

To effectively solve insufficient push force issues, follow a systematic approach:

Pressure Verification

Install a calibrated gauge directly at the cylinder inlet.

Difference from system pressure should be ≤0.5 MPa.

Leakage Test

Hold cylinder at end stroke for 5 minutes under rated pressure.

Pressure drop should not exceed 10% of the rated value.

Mechanical Inspection

Use laser alignment tools; deviation should be ≤0.05 mm/m.

Manually check for abnormal resistance.

Seal & Oil Check

Inspect seals and grooves for compliance.

Test oil contamination with particle counters (target NAS 9 or better).

Return Line Test

Measure backpressure at return port (should be ≤0.3 MPa).

Inspect and replace filters when clogged.

4. How Professional Cylinder Manufacturing Prevents Force Loss

At JW Hydraulic, we ensure maximum push force performance through:

Precision barrel honing (Ra 0.2–0.4 μm) to reduce leakage.

High-performance sealing systems matched to pressure, temperature, and oil medium.

Strict contamination control with advanced testing (NAS 7–9 standard).

Robust cylinder design minimizing side load sensitivity and misalignment risks.

👉 Investing in quality cylinder manufacturing not only prevents force loss but also reduces downtime, energy consumption, and maintenance costs for customers.

5. Conclusion

Insufficient cylinder push force is rarely caused by a lack of system pressure alone. Instead, it often results from internal leakage, seal wear, installation errors, or oil return restrictions. By applying structured diagnostics and relying on precision-engineered hydraulic cylinders, businesses can ensure reliable performance, longer service life, and lower total operating costs.

At JW Hydraulic, we specialize in designing and manufacturing custom hydraulic cylinders that maintain full push force even under the toughest industrial conditions.

📩 Contact us today to learn how our advanced cylinder solutions can enhance your equipment’s reliability and efficiency.