Hydraulic cylinders are the backbone of modern vehicle motion control systems. They transform hydraulic pressure into linear mechanical force, enabling vehicles to lift, tilt, steer, and brake with precision. Whether used in heavy trucks, construction machinery, or agricultural vehicles, vehicle hydraulic cylinders are essential for performance, safety, and productivity.

As an experienced hydraulic cylinder manufacturer in China, we specialize in designing and producing cylinders that meet strict international standards. In this guide, we’ll dive deeper into what makes vehicle hydraulic cylinders unique, their technical specifications, applications, and why choosing the right supplier is critical.

What is a Vehicle Hydraulic Cylinder?

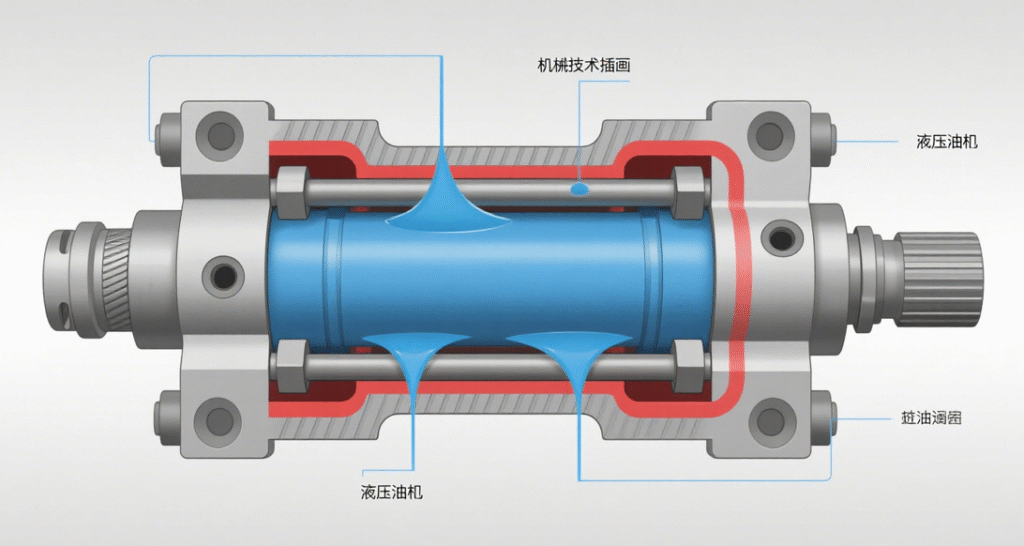

A vehicle hydraulic cylinder is a high-pressure actuator that uses hydraulic fluid to generate controlled movement. In vehicles, they are usually mounted in compact spaces and exposed to challenging environments, such as:

- High mechanical loads

- Extreme temperature changes

- Dust, water, and chemical exposure

- Continuous vibration and shock loads

Unlike general-purpose cylinders, vehicle hydraulic cylinders require:

Extended fatigue life under cyclic loading

Compact design with high power density

Sealed systems for leak-free performance

Key Features & Technical Requirements

Professional vehicle hydraulic cylinders are not just about force—they must meet engineering standards to guarantee reliability.

| Feature / Specification | Industry Standards / Requirements | Benefits for Vehicle Users |

|---|---|---|

| Working Pressure | 16–35 MPa (standard), up to 45 MPa for heavy-duty models | Handles demanding loads with safety margin |

| Sealing System | Parker, Hallite, NOK seals with multi-lip design | Prevents leakage, resists wear and temperature changes |

| Surface Finish | Honed tube Ra 0.2–0.4 μm, hard chrome or HVOF coating on rods | Extends service life, resists corrosion and scoring |

| Material Selection | 45# steel, ST52, 27SiMn, alloy steels, stainless steel | Strength + resistance to fatigue & corrosion |

| Testing Standards | 100% pressure test, endurance test (ISO 6020/6022, ISO 10100) | Ensures compliance with global quality requirements |

Common Applications in Vehicles

Vehicle hydraulic cylinders are tailored to different industries and vehicle types:

| Vehicle Type | Hydraulic Cylinder Functions | Typical Examples |

|---|---|---|

| Heavy Trucks | Telescopic lift, steering, suspension | Dump trucks, mining trucks |

| Construction Machinery | Boom, bucket, arm, and blade control | Excavators, wheel loaders, bulldozers |

| Agricultural Equipment | Steering, lifting, implement control | Tractors, harvesters, sprayers |

| Material Handling Vehicles | Lifting, tilting, mast extension | Forklifts, cranes, reach stackers |

| Special Purpose Vehicles | Multi-functional hydraulic actuation | Fire trucks, refuse trucks, concrete mixers |

Types of Vehicle Hydraulic Cylinders

Each cylinder type is engineered for a specific motion and space requirement:

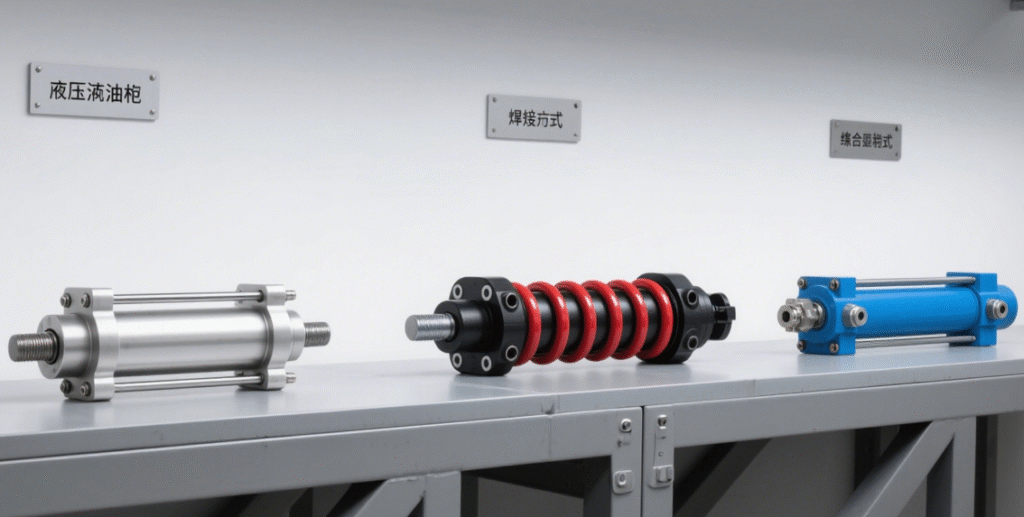

| Cylinder Type | Characteristics | Applications |

|---|---|---|

| Tie-Rod Cylinder | Economical, easy maintenance | Light-duty steering & lifting systems |

| Welded Cylinder | Compact, stronger end caps, harder to disassemble | Construction, agriculture, transport |

| Telescopic Cylinder | Multi-stage, very long stroke with compact design | Dump trucks, trailers, tipper trucks |

| Integrated Valve Cylinder | Cylinder + valve in one housing, reduces piping | Space-limited specialized vehicles |

| Position Sensing Cylinder | Built-in sensors for stroke feedback | Autonomous & smart vehicle systems |

Advanced Design Considerations

Professional buyers often evaluate cylinders based on more than just dimensions. Key factors include:

- Load Holding & Safety – Counterbalance valves and load-holding features prevent accidents in lifting applications.

- Efficiency – Optimized bore-to-rod ratios reduce energy consumption.

- Corrosion Resistance – For road salt, marine environments, or agricultural chemicals, special coatings (e.g., nickel-chrome, HVOF) are essential.

- Maintenance Cycles – Cylinders designed for easy seal replacement minimize downtime.

- Customization – Stroke length, mounting style (clevis, trunnion, flange), and special ports can be adapted to your vehicle design.

Why Choose Us as Your Vehicle Hydraulic Cylinder Supplier?

- Custom Manufacturing – We design cylinders based on your drawings and technical requirements.

- High-Quality Materials – Honed tubes, chrome-plated rods, and precision seals ensure durability.

- Advanced Machining & Testing – 100% tested for performance, leakage, and safety.

- Global Export Experience – Trusted by clients in Europe, USA, and Australia.

- Cost-Effective Solutions – Reliable cylinders at competitive prices.

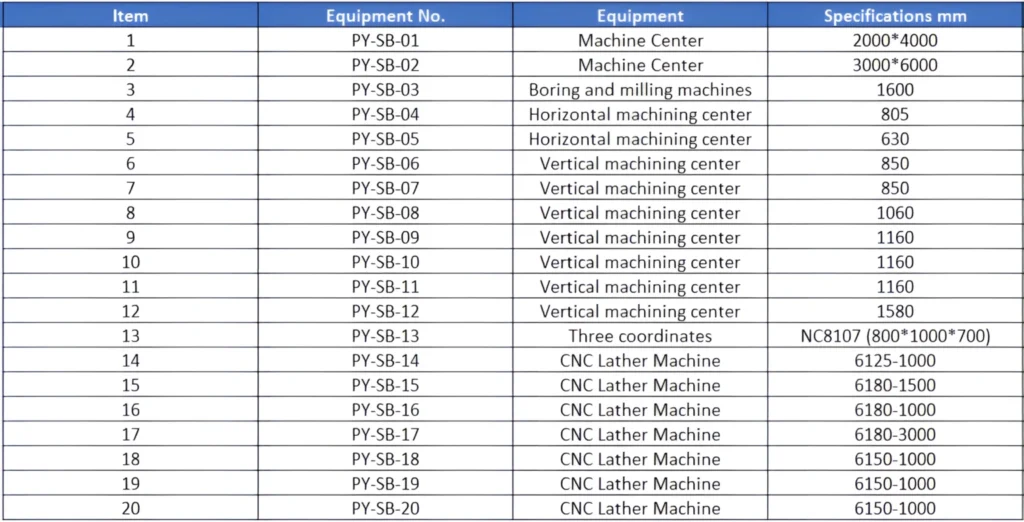

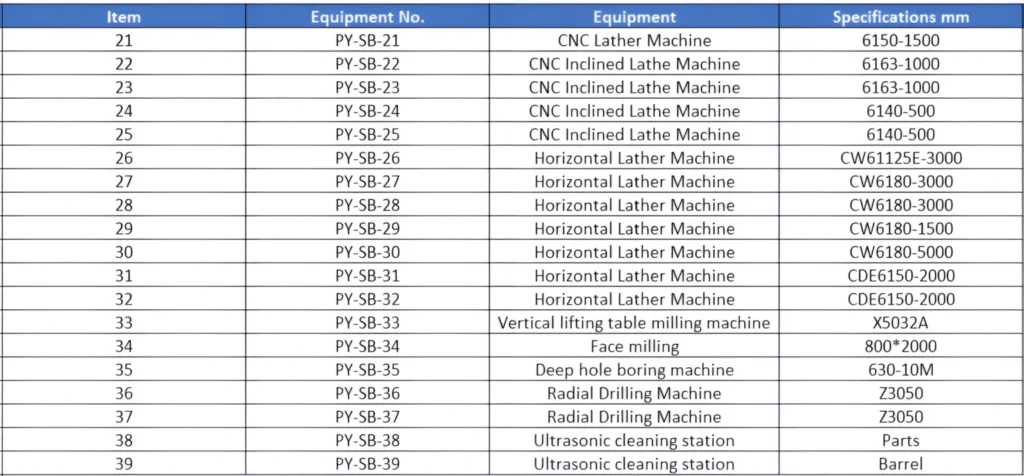

Main Equipment List

Final Thoughts

Vehicle hydraulic cylinders are essential for modern transportation, construction, and agricultural machinery. Choosing a reliable manufacturer ensures better performance, safety, and long-term cost savings.

If you are looking for custom hydraulic cylinders for vehicles, we are ready to support your project with professional design, manufacturing, and after-sales service.

👉 Contact us today to discuss your requirements and get a tailored solution!