Hydraulic cylinders are key actuators in machines. They create the force needed for lifting, pressing, rotating, and positioning. Different types of hydraulic cylinders serve unique roles depending on their design.

This guide introduces seven common hydraulic cylinder types with clear explanations of their structure, working principle, and uses.

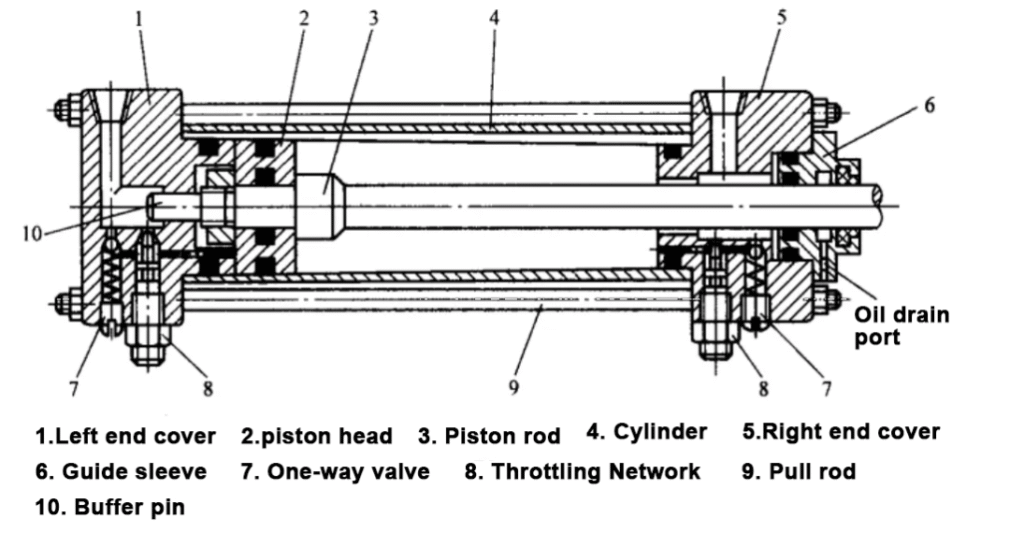

1.Double-acting piston hydraulic cylinder

A double-acting cylinder includes:

- Piston head (2)

- Piston rod (3)

- Cylinder body (4)

- End caps (1, 5)

- Guide sleeve (6)

- Tie rods (9)

End caps connect to the cylinder body with four tie rods. Each end cap has a buffer system with a check valve (7) and a throttle valve (8). This system cushions the piston at the end of its stroke and reduces impact.

When the piston retracts, the buffer pin (10) engages the end cap. Oil flows through the throttle valve, creating resistance that slows the piston. Adjusting the valve changes the resistance. During the return stroke, high-pressure oil enters the piston cavity through the check valve.

✅ Application: Precise positioning systems and equipment needing shock absorption.

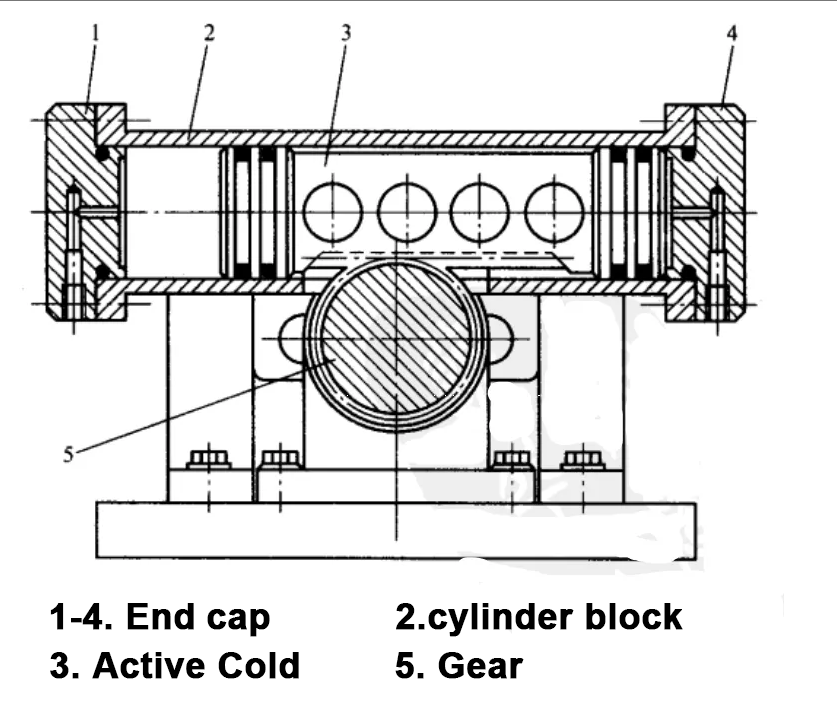

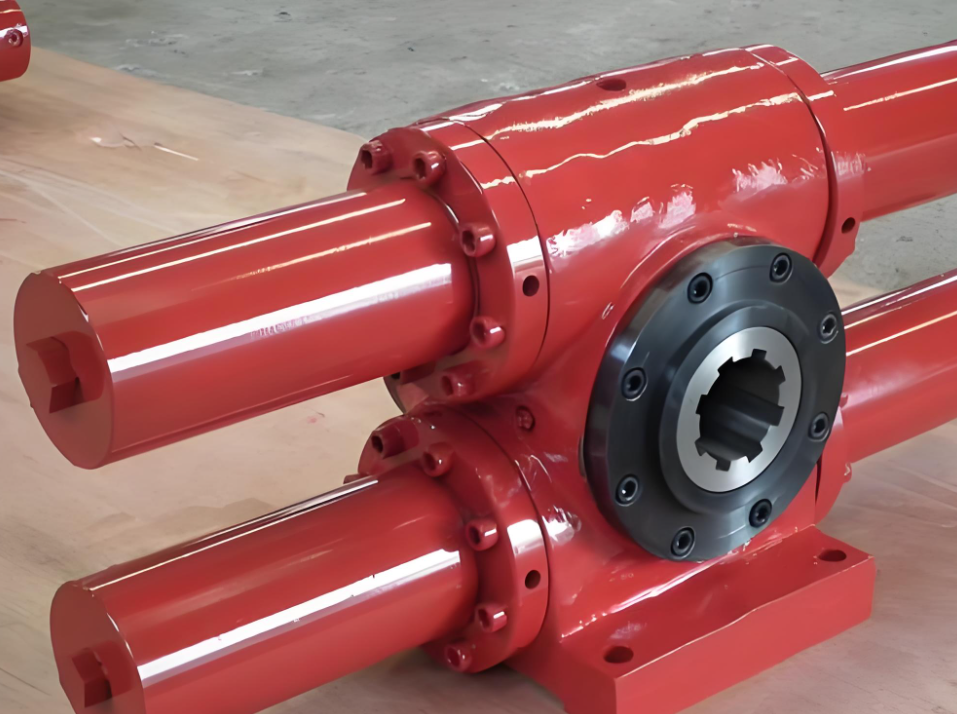

2.Rack hydraulic cylinder

In a rack-and-pinion cylinder, the piston (3) moves back and forth. This motion drives a rack, which rotates gear (5). Cushioning occurs through fixed orifices in the end caps (1, 4).

These cylinders deliver high torque. However, their positioning accuracy is lower than other types.

✅ Application: Heavy-duty rotating mechanisms with high load demands.

info@jwgroup.cc

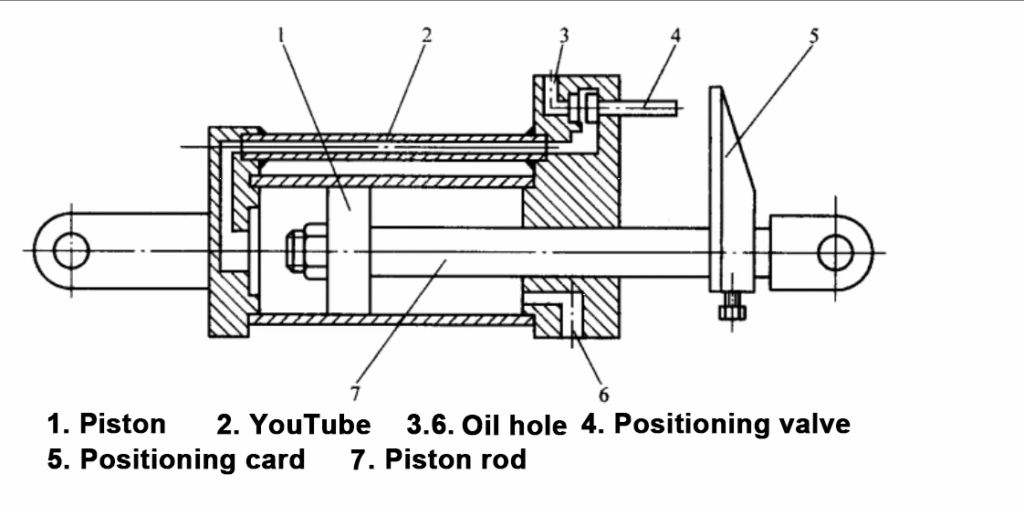

3. Hydraulic cylinder with piston stroke adjustment device

This cylinder uses a positioning card (5) on the piston rod (7). Operators can adjust it before use.

- Oil entering the right chamber through port (6) moves the piston (1) left.

- As the piston moves, oil exits through port (3).

- When the positioning card reaches the set point, it presses the positioning valve (4). This closes the outlet and stops the piston.

- Oil entering through port (3) reopens the valve, allowing the piston to move right.

✅ Application: Tasks requiring adjustable stroke and repeatable positions.

info@jwgroup.cc

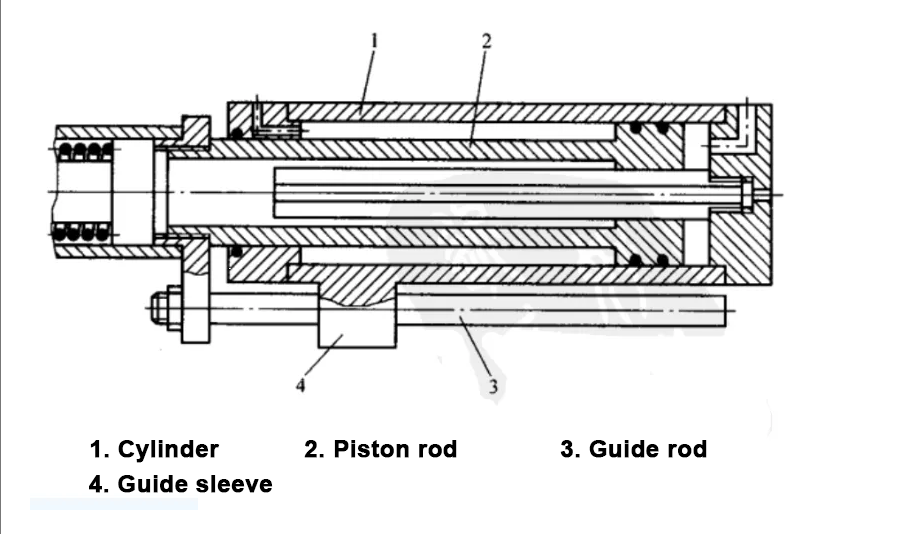

4. Hydraulic cylinder equipped with a guide device

This cylinder has a guide sleeve (4) on the body (1) and a guide rod (3) attached to the piston rod (2). The guide improves:

- Rigidity

- Stability at high speeds

- Resistance to bending wear

✅ Application: High-speed machinery and systems that handle heavy loads.

info@jwgroup.cc

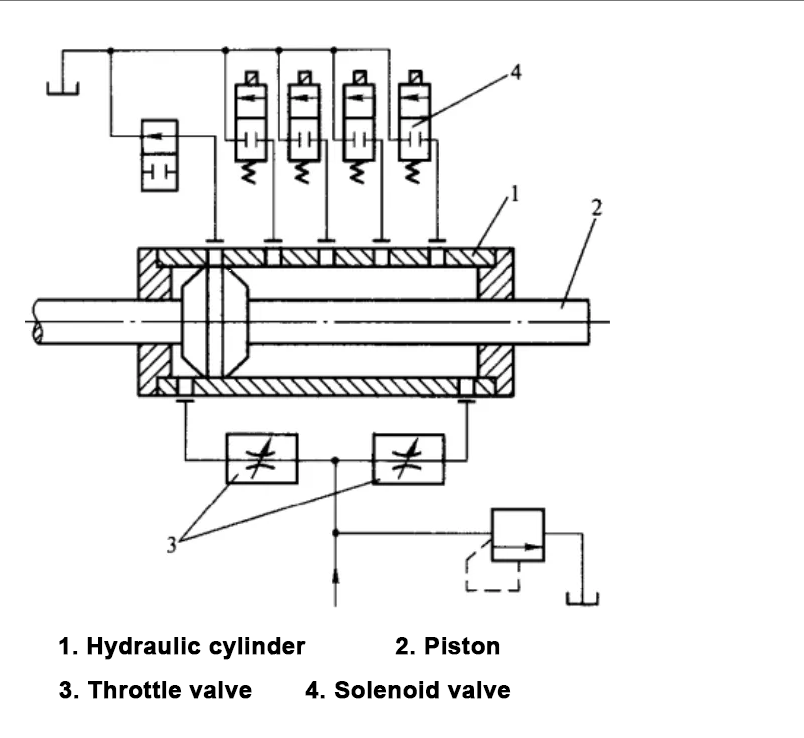

5.Multi-position hydraulic cylinder

The multi-position cylinder uses multiple oil ports and throttle valves (3). The cylinder body (1) connects to solenoid valves (4), which control oil flow to the tank.

When one chamber loses pressure, piston (2) moves toward the low-pressure side. It stops once both chambers reach balance. The piston can hold in different positions based on valve control.

✅ Application: Machines that require several piston stop points.

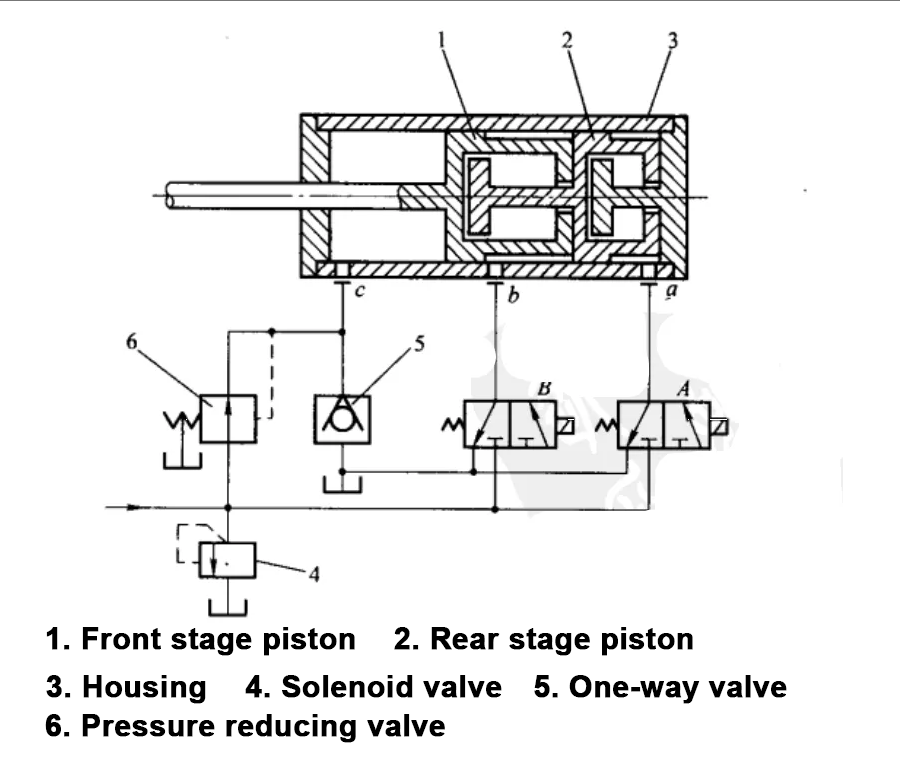

6. Stepper hydraulic cylinder

A stepper cylinder may have single or two stages. The front piston (1) also serves as the body for the rear piston (2).

It includes multiple inlets: high-pressure ports (a, b) and a low-pressure port (c). Oil flow controls the piston’s step length (L, 2L, or 3L).

- With no high-pressure oil, the piston stays at zero.

- Flow between ports a, b, and c moves the piston in precise steps.

✅ Application: Equipment needing controlled, step-by-step piston travel.

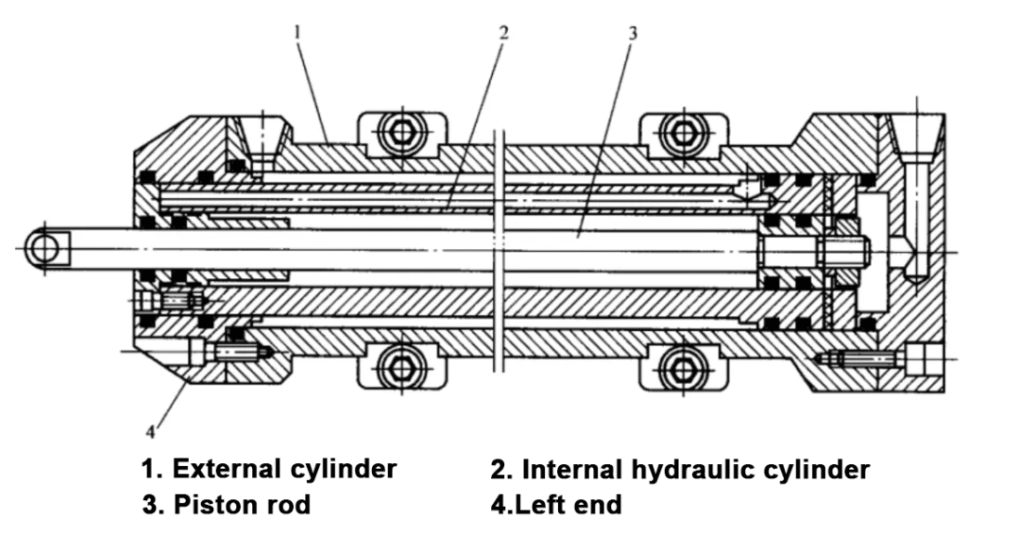

7. Telescopic hydraulic cylinder

A telescopic cylinder combines:

- External body (1)

- Internal cylinder (2)

- Internal piston rod (3)

When oil enters the left chamber, it first pushes the internal cylinder, then the piston rod. This staged action delivers a long stroke while keeping the retracted size small.

✅ Application: Construction and transport machinery where space is limited but stroke length is important.

Applications of Hydraulic Cylinders

Hydraulic cylinders are widely used in:

- Construction machinery such as excavators and cranes

- Industrial presses and automation equipment

- Forklifts and lifting platforms

- Heavy-duty transport vehicles

Why Choose JW Hydraulic?

At JW Hydraulic, we design and manufacture custom hydraulic cylinders for many industries. Our products feature:

- Strong materials and precision production

- Stable performance and long service life

- Competitive global pricing