As a hydraulic cylinder manufacturer, we often observe a critical oversight in industrial maintenance: hydraulic cylinders placed in long-term storage without periodic operation. Although this practice may seem harmless, it can quietly turn brand-new, high-performance components into costly liabilities—sometimes before they ever enter service.

So, do stored hydraulic cylinders really need “exercise”? The answer is yes. Much like athletes in hibernation, hydraulic cylinders rely on movement to maintain performance. Without regular operation, their condition can steadily decline.

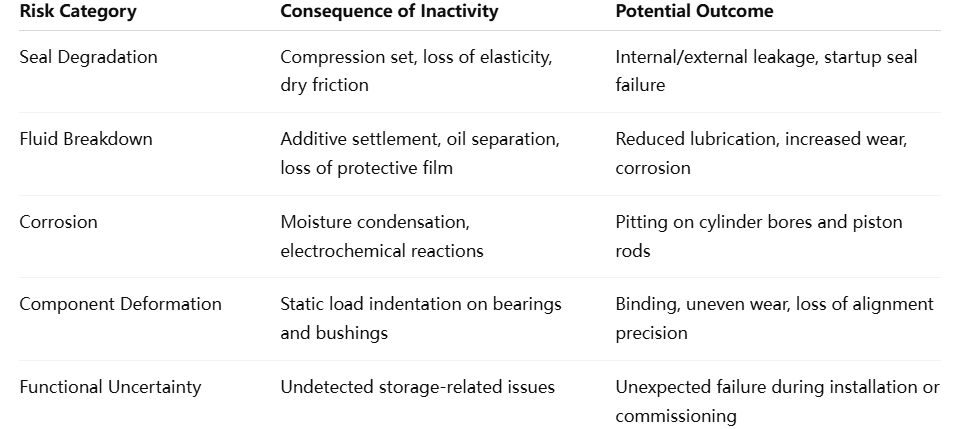

The Hidden Risks of Inactivity in Stored Hydraulic Cylinders

When hydraulic cylinders remain inactive for extended periods, several degradation mechanisms begin to develop. As a result, reliability and service life may be significantly reduced.

Why Periodic Operation Is Essential for Stored Hydraulic Cylinders

1. Seal Preservation – Your First Line of Defense

Seals are designed to move. However, when they remain compressed for long periods, permanent deformation can occur.

Therefore, periodic movement helps redistribute stress across the seal profile. In addition, circulating hydraulic oil restores the lubrication film on sealing lips, which prevents dry aging. Over time, this also helps avoid adhesion between seals and metal surfaces that could cause tearing during startup.

2. Hydraulic Fluid Integrity Management

Hydraulic oil is a carefully balanced formulation. During prolonged stillness, additives such as anti-wear and anti-corrosion agents can settle.

As a result, lubrication performance may decline. Regular circulation keeps these additives evenly distributed and maintains full protective capability.

Pro tip: If a cylinder has been stored for more than 12 months, oil replacement before commissioning is strongly recommended.

3. Corrosion Prevention

Temperature changes often lead to moisture condensation inside stored cylinders. Unfortunately, water is one of the biggest threats to hydraulic systems.

For this reason, periodic operation disperses moisture throughout the fluid instead of allowing it to concentrate in one area. Meanwhile, extending and retracting the piston rod reapplies a protective oil film across internal and external surfaces.

4. Structural Integrity Maintenance

Bearings and guide bushings can suffer localized deformation when exposed to constant static loads.

Consequently, controlled movement redistributes contact points. This helps maintain alignment accuracy and ensures smooth, predictable operation when the cylinder is finally installed.

5. Verification of Operational Readiness

Periodic operation is not only preventive—it is also diagnostic.

In practice, each operation cycle allows you to:

Verify seal integrity and check for leaks

Confirm smooth piston movement

Validate sensor functionality (for smart cylinders)

Document cylinder condition for maintenance and warranty records

Best-Practice Stored Hydraulic Cylinder Maintenance Protocol

Recommended Frequency

Standard environments: Every 3–6 months

High humidity or fluctuating temperatures: Every 1–3 months

Critical applications: Monthly inspection and quarterly full-stroke cycling

Step 1: Assessment and Preparation

Before operation, review all storage and maintenance records. At the same time, ensure the work area is clean to prevent contamination. For sensitive or high-value cylinders, using a dedicated test stand with filtered hydraulic fluid is strongly advised.

Step 2: Setup and Connection

Whenever possible, install the cylinder on a test bench using clean, filtered fluid that meets specification.

Alternatively, a closed-loop circuit with a clean power unit or manual pump may be used. In every case, follow lock-out/tag-out procedures and confirm the cylinder is securely mounted before pressurization.

Step 3: Movement Protocol Execution

Begin by applying pressure slowly. During this stage, listen for abnormal noise and watch for leaks.

Next, perform 5–10 full extension and retraction cycles using smooth, controlled motion. Avoid rapid or jerky movement. Finally, pause briefly at full extension and retraction to confirm complete travel.

During operation, monitor:

Pressure stability

Consistent movement

External leakage at ports, seals, and connections

Step 4: Completion and Storage Positioning

After cycling, fully retract the piston rod into the cylinder barrel.

This step is important because it:

Minimizes exposed rod surface vulnerable to corrosion

Reduces condensation risk inside the cylinder

Protects precision rod surfaces

Once complete, safely depressurize the system and install protective caps on all ports.

Step 5: Documentation and Follow-Up

Finally, record the date, number of cycles, and any observations in the maintenance log. If irregularities are found, address them before commissioning. In addition, schedule the next operation based on environmental conditions.

Special Storage Considerations

Dry-stored cylinders: Always consult the manufacturer before adding fluid

Extreme environments: Apply a light protective coating to exposed rod surfaces

Long-term storage (over two years): Use preservation fluids and specialized procedures

The Manufacturer’s Perspective: Our Recommendation

Based on long-term field experience, we recommend that customers:

✅ Document storage conditions

✅ Maintain individual cylinder maintenance logs

✅ Use preservation fluids for storage beyond 12 months

✅ Implement rotational storage for large inventories

✅ Train personnel on proper storage practices

✅ Use barcode or RFID tracking for maintenance scheduling

Economic Impact: Prevention vs. Replacement

| Cost Factor | Preventive Maintenance | Reactive Replacement |

|---|---|---|

| Material cost | Minimal | $500–5,000+ rebuild |

| Labor | 0.5–1 hour quarterly | 8–40 hours repair |

| Downtime | Planned and minimal | Unplanned, days or weeks |

| Contamination risk | Low | High |

| Warranty status | Maintained | Often voided |

| Safety risk | Controlled | Elevated |

Conclusion: An Ounce of Prevention

Periodic operation is not simply maintenance—it is preservation.

With less than 30 minutes of effort each quarter, stored hydraulic cylinders can remain close to factory condition. In fact, regular operation can prevent up to 90% of storage-related failures, while also protecting capital investment and warranty coverage.

At JW Hydraulic, we engineer hydraulic cylinders for long-term durability. However, even the best engineering depends on proper storage practices. That is why our technical team provides customized storage and preservation guidance with every major shipment.

Don’t let valuable hydraulic assets suffer from “out of sight, out of mind.”

Contact us to receive our Hydraulic Storage & Preservation Guide and learn how our cylinders are designed for reliable performance—even after extended storage.