Introduction: When Speed Meets Efficiency

In modern OEM equipment design—whether in waste compaction, injection molding, metal forming, or recycling systems—engineers constantly face a fundamental trade-off:

How to achieve both high motion speed and high pressing force without increasing energy consumption.

A well-engineered regenerative hydraulic circuit provides the answer.

By reusing hydraulic energy internally, regenerative (also called reverse-phase or differential) circuits allow equipment to operate faster during low-load phases and stronger during high-load phases—all with a single pump.

But excellent circuit design only becomes reality when paired with high-performance cylinders and valves capable of withstanding the stress of constant flow reversal, pressure switching, and synchronized operation.

That’s where JW Hydraulic excels.

With over 20 years of manufacturing experience, JW provides large-rod diameter cylinders, precision valve systems, and integrated hydraulic manifolds optimized for regenerative applications—helping OEMs achieve greater performance, reliability, and energy efficiency.

How the Regenerative Circuit Works

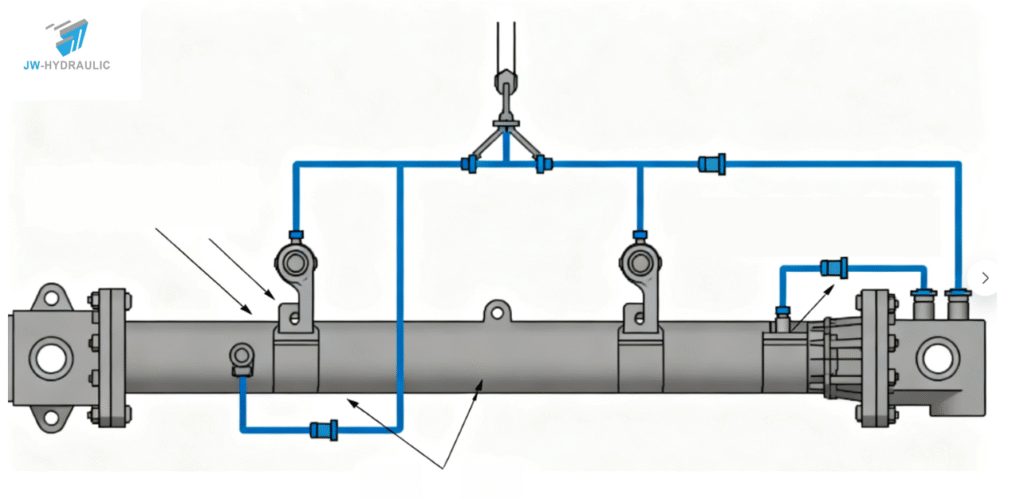

1. Rapid Advance Phase (High Speed / Low Force)

During rapid motion, the pump delivers oil to the rod ends of two large-rod cylinders.

Instead of sending discharge oil from the bore side back to the tank, it is redirected to the opposite cylinder’s rod side, effectively amplifying the flow.

This configuration produces high-speed movement under low load, while reducing the pump’s displacement requirement.

Callouts:

“Flow Amplification”

“High Speed / Low Force”

2. High-Pressure Phase (Pressing / Compacting)

As the load increases, the system automatically shifts:

The pump output is redirected to the bore sides of both cylinders.

The rod ends are interconnected to equalize pressure.

This stage delivers maximum pressing force for heavy-duty applications such as compacting, extrusion, or forming.

Callouts:

“High Force / Low Flow”

“Energy Reuse”

This push-pull synchronization minimizes energy waste and reduces the size requirements for pumps and directional valves—lowering system cost without compromising performance.

JW Expert Insight: Why Cylinder Design Defines Circuit Success

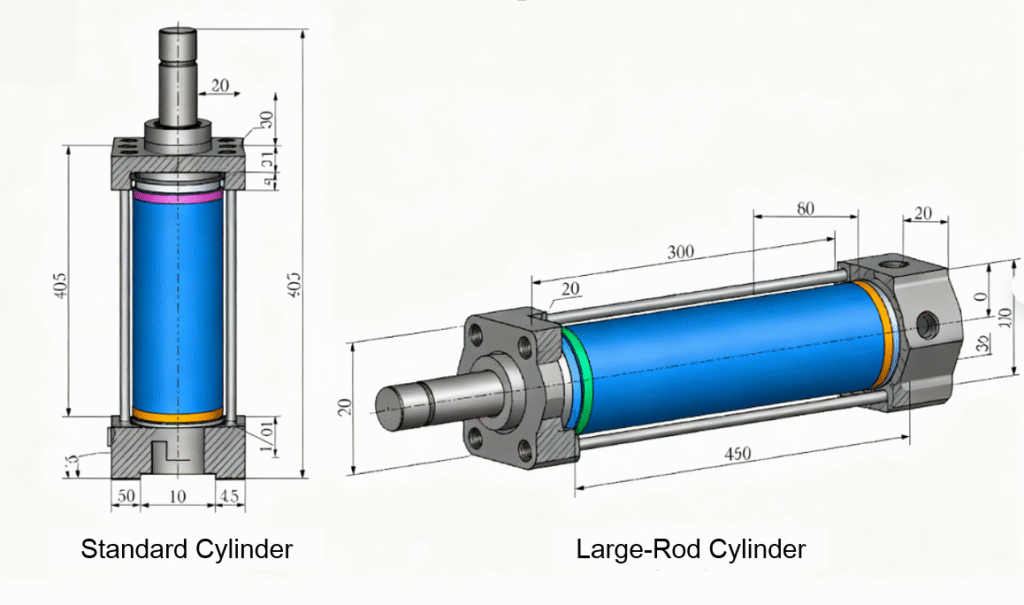

Not every hydraulic cylinder can perform effectively in a regenerative system.

The continuous reversal of flow direction and pressure demands rigid construction, precision sealing, and optimized internal geometry.

That’s why JW Hydraulic’s Large-Rod Diameter Series is purpose-built for this environment.

| Key Feature | JW Solution & Client Benefit |

|---|---|

| High Rod-to-Bore Ratio (up to 0.7) | Enables greater flow amplification and balanced pressure transitions. |

| Precision-Machined Glands & Seals | Prevents micro-leakage and eliminates jerky motion under rapid switching. |

| Reinforced Barrel & End Cap Design | Ensures structural rigidity, minimizing deflection and extending fatigue life. |

| Optional Valve Integration | Pre-mounted manifolds simplify installation and reduce leakage risk. |

Key Considerations for Customizing Cylinders in Regenerative Circuits

1. Piston Rod Design & Material

JW uses induction-hardened, high-yield steel rods with hard chrome or nickel-chrome plating, providing exceptional wear resistance and column strength.

This allows long-stroke applications to remain stable and precise, even under unbalanced load conditions.

2. Advanced Sealing Technology

Our cylinders employ shock-resistant sealing systems engineered to withstand pressure peaks exceeding 35 MPa and rapid pressure reversals—preventing seal extrusion and premature wear.

3. Structural Rigidity

JW cylinders use optimized wall thickness and reinforced bearing support, reducing deflection and ensuring perfect stroke alignment during synchronized operation.

4. Integration Options

To streamline OEM integration, JW offers:

Cylinders with built-in sensors for real-time position monitoring

Pre-assembled valve blocks for space-efficient installation

Plug-and-play hydraulic modules for multi-cylinder synchronization

| Parameter | Standard Cylinder | JW Regenerative-Optimized Cylinder |

|---|---|---|

| Flow Loss (Rapid Advance) | High | ↓ 15% Lower |

| Cycle Stability | Moderate | Stable under 10⁶ cycles |

| Fatigue Life | 10⁵ cycles | 10⁶+ cycles |

| Hydraulic Shock Resistance | Average | Excellent (tested to 35 MPa) |

Circuit Design & JW Integrated Components

| Component | Function | JW Solution |

|---|---|---|

| Cylinder | Energy transfer and motion control | JW Large-Rod Series – optimized rod-to-bore ratio for regenerative operation |

| Directional Control Valves (4/3) | Manage rapid and pressure modes | JW DSV Series – high-response, low-leakage design |

| Rapid Motion Enable Valve (Pilot-Operated) | Flow path switching for speed control | JW RCV Series – oversized flow area, low throttling loss |

| Re-Phasing Valve | Synchronizes cylinder movement | JW Synchron Valve System – <10 ms response time, zero drift |

| Accumulator (Optional) | Reduces pump demand and smooths flow | JW EnergySaver Module – compact accumulator package |

JW Integrated Advantage:

Choosing JW Hydraulic means acquiring a fully compatible ecosystem of components.

Each element—from the cylinder to the control valve—is precision-engineered for regenerative performance, reducing interface risk, simplifying procurement, and maximizing system uptime.

Engineering Quality Assurance

Oil Cleanliness: Every JW cylinder meets ISO 4406 18/16/13 or better before delivery.

System Safety: JW engineers calculate the optimal safety factor for your design and provide pressure rating certifications upon request.

Thermal Stability: Oversized internal flow paths reduce throttling losses and temperature rise during high-duty cycles.

Conclusion: From Concept to Competitive Advantage

A regenerative hydraulic circuit is more than an energy-saving concept—it’s a pathway to smarter, faster, and more profitable machinery.

But true success depends on the quality of your components.

At JW Hydraulic, we transform hydraulic theory into performance reality.

Our large-rod cylinders, precision valves, and integrated manifolds empower OEMs to achieve up to 20% higher system efficiency and faster cycle times—with proven long-term reliability.

🔧 Partner with JW Hydraulic to make your next machine design more competitive.

📩 Share your design parameters, and our engineering team will provide a customized Cylinder & Component Selection Proposal.

This is a topic which is near to my heart…

Many thanks! Where are your contact details though? https://tiktur.ru/

I’m glad to hear you’re interested in the content I posted. If you have any inquiries about hydraulic cylinders and their components, please feel free to contact jane.wang@jwgroup.cc