In heavy machinery, hydraulic cylinders do much more than move equipment. They carry heavy loads, run in harsh environments, and must stay reliable. But what makes one cylinder last longer and perform better than another?

The answer is simple: precision machining at every step of production.

At JW Hydraulic, we manufacture hydraulic cylinders and components in China. Our advanced machine park allows us to control quality from start to finish. As a result, every cylinder delivers stable performance, long service life, and lower operating costs.

Below is how our machining technology helps you get better results.

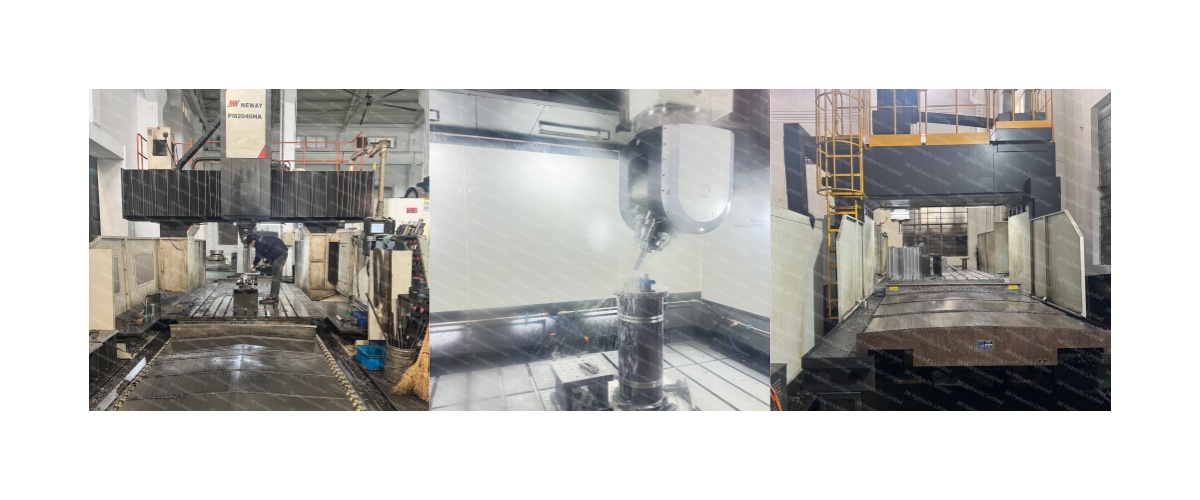

High-Precision Gantry Milling for Large Components

Manufacturing Challenge:

Large cylinder blocks and heads must stay stable and perfectly aligned. Otherwise, side-loading and seal failure can occur.

Our Capability:

Large work envelope for components up to 6 m × 3 m

High-torque spindles for heavy steel cutting

Multi-pallet system for continuous production

Your Benefit:

As a result, mounting surfaces stay flat and bore alignment stays true. This is essential for construction and mining cylinders.

5-Axis CNC Milling for Complex Cylinder Parts

Manufacturing Challenge:

Some components, such as port blocks and custom heads, need complex shapes and tight tolerances.

Our Capability:

True 5-axis machining for all angles in one setup

High-RPM spindles for smooth surfaces

On-machine probing for accuracy

Your Benefit:

Therefore, seal grooves fit perfectly, internal oil passages flow smoothly, and your cylinder operates without leaks or pressure loss.

Precision Honing for Perfect Cylinder Bores

Manufacturing Challenge:

The bore surface must hold oil, support seals, and reduce internal friction.

Our Capability:

Automated control of cross-hatch patterns

Correction of taper and waviness

Ultra-fine surface finish down to Ra < 0.2 μm

Your Benefit:

As a result, the piston seal moves smoothly, reduces wear, and improves overall efficiency and cylinder lifespan.

Rod Grinding, Chrome Plating, and Polishing

Manufacturing Challenge:

Piston rods must resist corrosion, sliding wear, and scoring while maintaining a mirror-smooth seal surface.

Our Capability:

Precision grinding to tight tolerances

Controlled hard-chrome plating for long-term durability

Polishing to Ra < 0.05 μm

Your Benefit:

Consequently, rod seals last longer, leakage is minimized, and the cylinder performs reliably even in harsh conditions.

Why This Precision Matters for Your Business

You may ask, “How does all this technical work help my operation?” Here is the direct value:

Lower Total Cost of Ownership: Better machining means longer service life and less downtime.

Higher Machine Uptime: Reliable cylinders keep your projects moving.

Better Equipment Performance: Smooth and consistent motion improves control.

A Safer Choice: With stable quality, you reduce the risk of unexpected failures.

In short, precision machining is not optional. It is the foundation of every high-quality hydraulic cylinder.

Ready to Improve Your Equipment Performance?

If you want hydraulic cylinders that deliver longer service life, better sealing, and lower maintenance costs, we are here to support you.

Contact us for a technical discussion or request a data sheet.

We’d love to know:

Which performance factor matters most to you—service life, leak resistance, or power density?

Share your thoughts in the comments!