Definition of Plunger Cylinders

A plunger cylinder is a type of single-acting hydraulic cylinder. It operates in one direction through hydraulic pressure, while the return stroke relies on external forces—such as gravity, counterweights, or springs.

The plunger rod typically has a large diameter, often close to the bore size. For instance, a plunger with a 125 mm bore may have a 120 mm rod, or in some cases, the rod and bore diameter are the same (e.g., a 400 mm rod with a 400 mm bore).

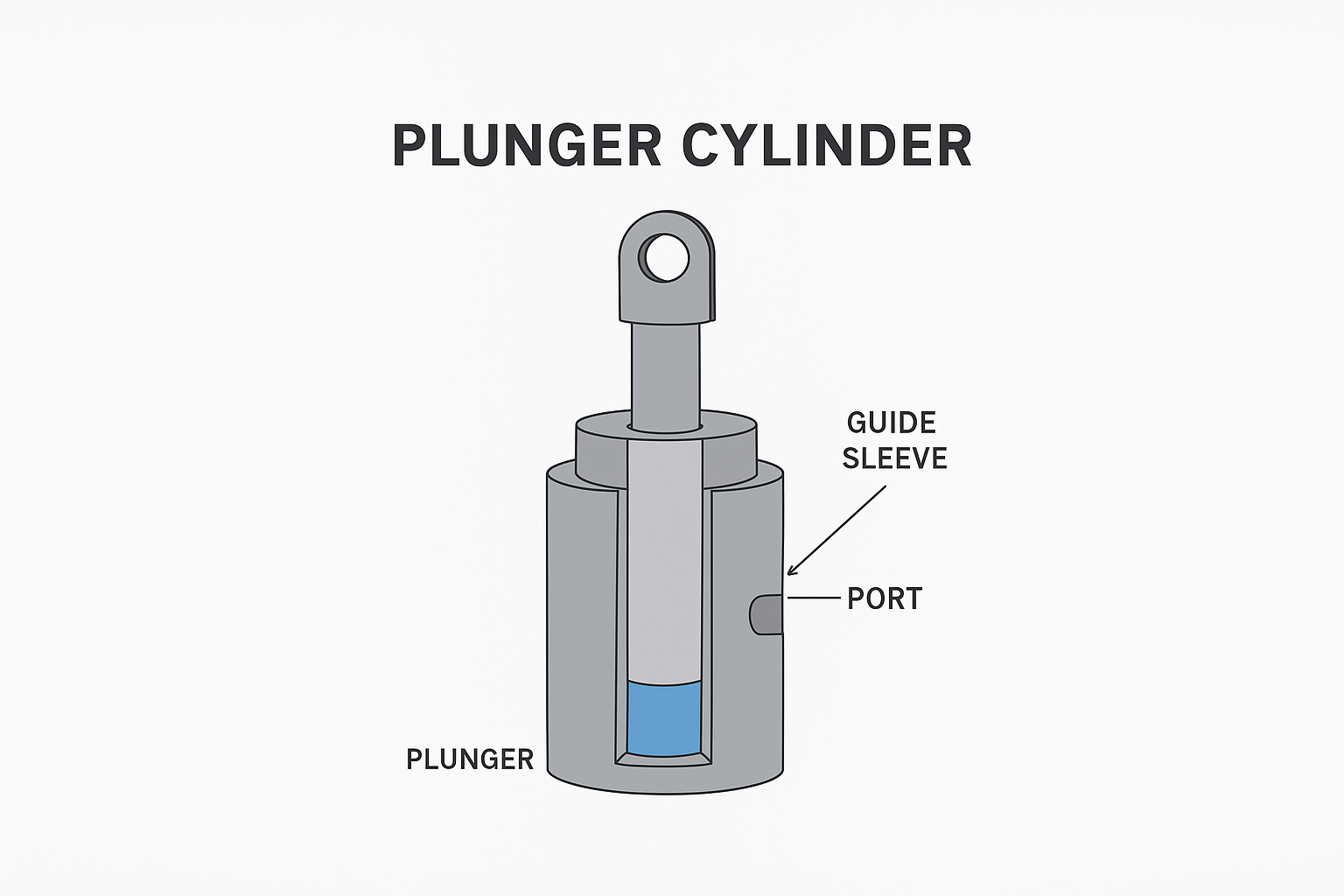

During operation, the plunger is guided by a guide sleeve located on the cylinder head. Because the plunger does not contact the inner wall, the cylinder barrel does not require finishing. This design makes plunger cylinders especially suitable for long-stroke applications.

Structure of Plunger Cylinders

The key structural features of a plunger cylinder include:

- Single-acting design – Movement occurs in one direction by hydraulic pressure, while the return stroke depends on external forces.

- Simplified cylinder barrel – The plunger is supported only by the guide sleeve and does not contact the cylinder barrel, making the barrel easier to manufacture.

- High rigidity – Since the plunger is constantly under pressure during operation, it must be designed with sufficient strength and rigidity.

- Vertical installation advantage – Due to its weight, the plunger may sag when installed horizontally, leading to seal and guide wear. Vertical installation helps avoid this issue and extends service life.

Working Principle of Plunger Cylinders

Plunger hydraulic cylinders generate movement in one direction under hydraulic pressure. The return stroke is driven by gravity, springs, or external forces. To achieve two-way motion, plunger cylinders are often used in pairs.

Because the plunger is guided only by the cylinder head sleeve and does not directly engage with the cylinder wall, the barrel does not require precise finishing. The plunger end is always pressurized, which requires it to be thick and durable.

When mounted vertically, plunger cylinders operate with maximum stability. However, if horizontal installation is necessary, the plunger is usually manufactured with seamless steel tubing to reduce weight and improve balance.

JW’s Expertise in Plunger Cylinder Design

Plunger cylinders are widely used in hydraulic presses, forklifts, lifting platforms, and other heavy-duty equipment.

At JW Hydraulic, we design plunger cylinders with a focus on three main aspects:

- Functionality – Optimizing the size, stroke length, and seal selection for reliable performance.

- Applicability – Designing suitable installation methods and structural configurations tailored to customer needs.

- Production technology – Enhancing machining processes while controlling costs to deliver competitive pricing.

By combining technical expertise with industry experience, JW provides customized plunger cylinder solutions with stable quality, long service life, and cost efficiency for global clients.