In every hydraulic cylinder, the piston rod works as the key connection between high internal pressure and harsh external environments. Its surface treatment—especially hard chrome plating—directly influences cylinder lifespan, sealing stability, and operating efficiency.

At JW Hydraulic, we know that outstanding performance comes from strict control over every detail. Therefore, we select plating technologies based on the technical needs of each application. The three common processes—Vertical Plating, Horizontal Plating, and Through-Type Continuous Plating—each offer different advantages.

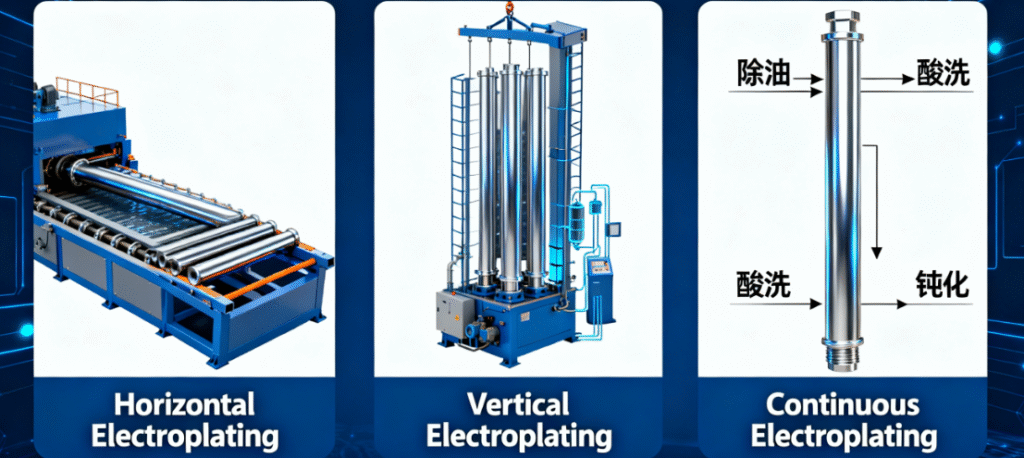

Part 1: Core Plating Technologies Explained

1. Vertical Plating

In this method, the rod hangs vertically in a deep tank. The setup is simple; however, gravity often causes uneven coating thickness. The top section may become thinner, while the bottom becomes thicker. In addition, trapped air can create pinholes.

2. Horizontal Plating

During horizontal plating, the rod lies flat and rotates at a steady speed. Because the rod moves continuously, the coating becomes evenly distributed. For this reason, the method is widely used in industries that demand stability, efficiency, and high quality.

3. Through-Type Continuous Plating

This process moves the rod through a compact “plating tunnel” while rotating. As a result, very long rods can be coated with exceptional consistency. It is the preferred choice for large-scale and continuous production.

Part 2: How Plating Choice Impacts Cylinder Performance

1. Coating Uniformity & Wear Resistance

Vertical Plating: Uneven thickness causes inconsistent wear. As a result, seals age faster and localized damage appears sooner.

Horizontal Plating: Steady rotation produces excellent uniformity. Because wear remains consistent, seal life increases.

Continuous Plating: Ultra-long rods gain highly stable thickness, which reduces weak points along the entire stroke.

2. Coating Adhesion & Structural Strength

Vertical Plating: Static conditions allow impurities or bubbles to stay on the surface, which may lead to micro-cracks.

Horizontal Plating: Forced convection removes gas and impurities. As a result, the coating becomes denser and more durable.

Continuous Plating: This method delivers the highest adhesion and density, making it ideal for extreme loads or shock conditions.

3. Surface Finish & Sealing Performance

Vertical Plating: Variations in roughness can increase friction and long-term leakage.

Horizontal Plating: The process creates a stable, mirror-like surface (Ra < 0.05 µm). Therefore, seals run smoothly with reduced friction.

Continuous Plating: The surface remains extremely clean with minimal defects, which is essential for servo cylinders and high-pressure systems.

4. Production Efficiency & Application Scope

Vertical Plating: Works best for low-volume jobs, repairs, and prototypes.

Horizontal Plating: Fits high-volume production in industries such as construction, mining, and agriculture.

Continuous Plating: Designed for ultra-long cylinders and large manufacturing runs, such as shipbuilding or metallurgical equipment.

Part 3: Purpose-Driven Process Selection

We match each plating process to the cylinder’s mission. For most industrial and mobile equipment, Horizontal Plating gives the ideal balance of precision, reliability, and cost-effectiveness. Therefore, it remains our primary process.

When customers require extremely long strokes or special performance, we work with advanced plating partners to offer Through-Type Continuous Plating. This ensures the same level of protection across every millimeter of the rod.

Conclusion: The Process Defines the Performance

Choosing the right piston rod plating method plays a major role in determining reliability, service life, and total cost of ownership.

Vertical Plating: Flexible and affordable for small batches.

Horizontal Plating: The global standard for consistent, long-term performance.

Continuous Plating: The premium solution for ultra-long and heavy-duty applications.

At JW Hydraulic, we integrate plating, metallurgy, machining, and quality control into one complete system. As a result, every cylinder delivers stable, dependable performance.

If you are selecting cylinders for a critical project, we welcome you to connect with us. The right plating technology can significantly improve durability and long-term value.