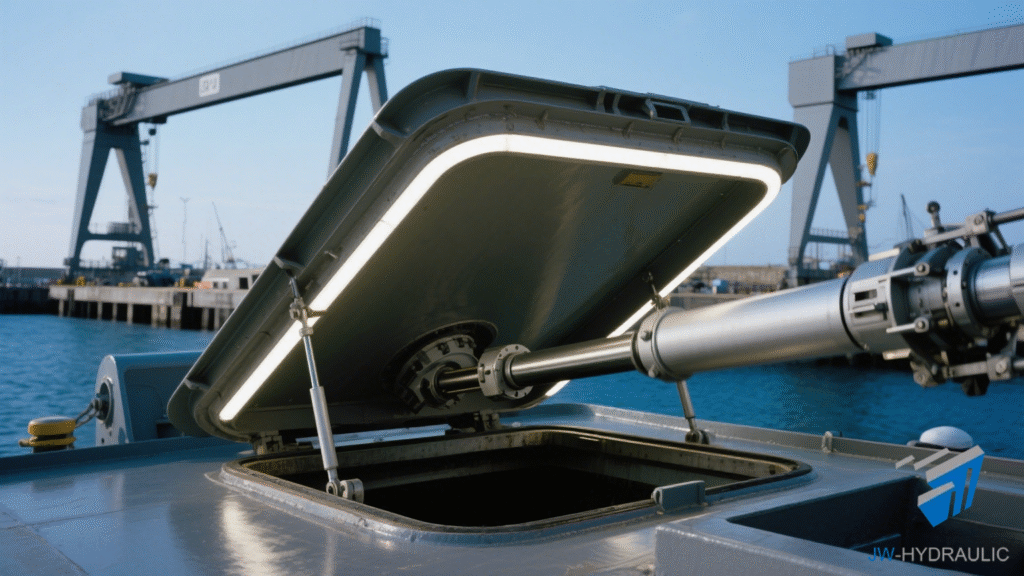

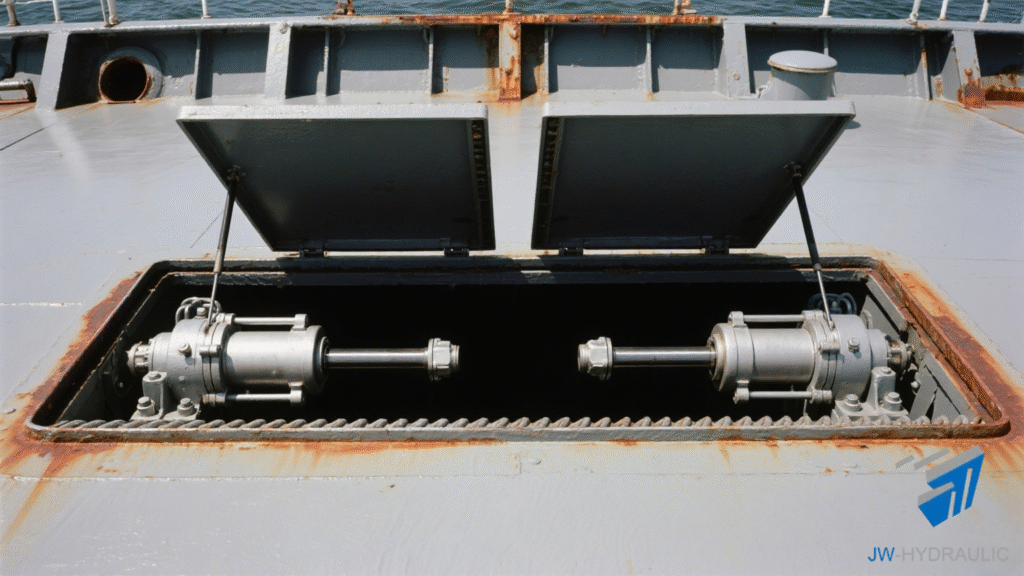

Modern intelligent hydraulic cylinders installed on ship hatch cover systems

The Shift Toward Smarter Marine Systems

The maritime industry is undergoing rapid digital transformation. With growing emphasis on efficiency, safety, and automation, intelligent ship equipment is becoming standard across commercial and defense fleets. According to recent market studies, the connected ship sector was valued at over USD 7.6 billion in 2023 and is projected to expand steadily through 2032.

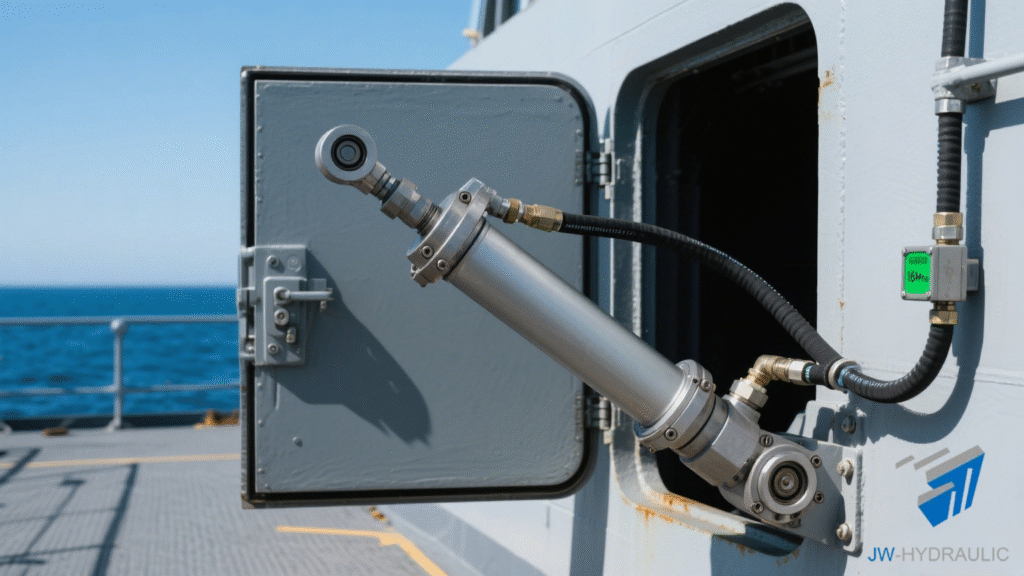

This trend is creating strong demand for intelligent hydraulic solutions, particularly for ship hatch cover systems. By integrating advanced sensors, remote monitoring, and predictive control technologies, hatch covers are now safer, more reliable, and more cost-effective than ever before.

How Intelligent Hatch Cover Hydraulic Cylinders Operate

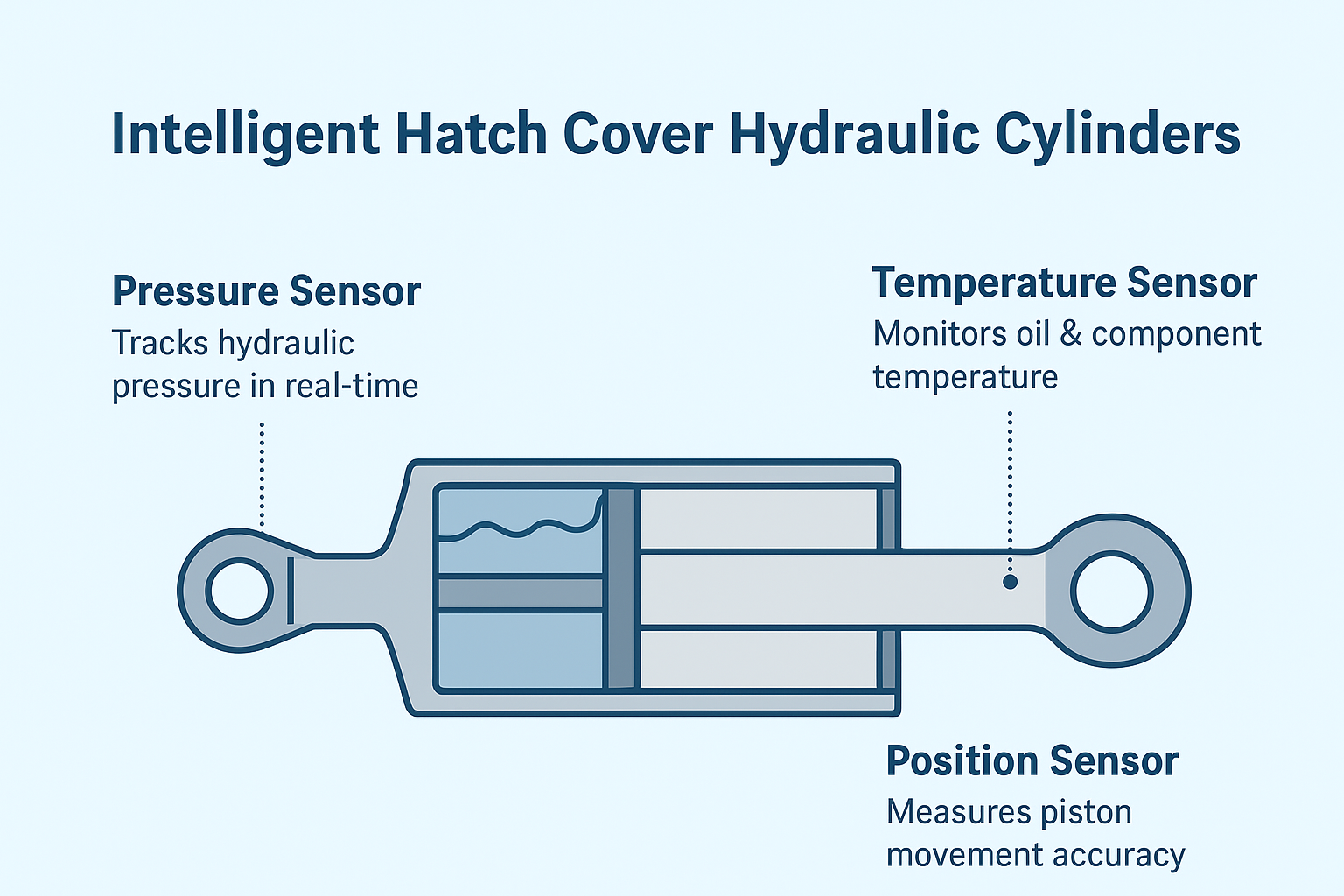

| Sensor Type | Function | Benefits for Ship Operators |

|---|---|---|

| Pressure Sensor | Tracks hydraulic pressure in real-time | Early leak detection, pump issue alerts |

| Temperature Sensor | Monitors oil & component temperature | Prevents overheating, detects seal friction |

| Position Sensor | Measures piston movement accuracy | Ensures smooth hatch cover operation |

All sensor data is transmitted to a central control unit, where algorithms analyze performance trends and initiate corrective actions. This closed-loop monitoring system allows early detection of faults, automatic safety adjustments, and optimized cylinder performance.

Key Advantages for Ship Operators

Real-time data monitoring for safe and efficient hatch cover operations

- Enhanced Safety – Real-time monitoring predicts failures before they occur, minimizing the risk of sudden breakdowns during voyages. Emergency auto-adjustments keep hatch covers secure even under heavy sea loads.

- Higher Efficiency – Remote control and diagnostics reduce manual involvement, saving time and labor. Data analytics support operational optimization and energy savings.

- Lower Costs – Predictive maintenance extends component life, prevents unplanned downtime, and reduces expensive emergency repairs.

Cost & Benefit Overview

| Feature | Traditional Cylinders | Intelligent Cylinders |

|---|---|---|

| Safety Monitoring | Manual inspection | Real-time smart sensors |

| Maintenance Approach | Reactive (after failure) | Predictive & proactive |

| Operational Control | On-site only | Remote + automated |

| Long-Term Cost Efficiency | Medium | High |

Looking Ahead: Smarter Marine Hydraulics

With continuous progress in AI, IoT, and automation, the next generation of hatch cover hydraulic cylinders will feature:

- Machine learning algorithms for predictive diagnostics.

- Stronger, corrosion-resistant materials for longer service life in harsh marine conditions.

- Integration into autonomous vessels, where reliable automated hatch operation is critical.

Intelligent hydraulic cylinders are no longer optional—they are becoming a core element of modern shipbuilding.

Why Choose Us

Our advanced manufacturing facility in China – full in-house machining and testing

As a leading hydraulic cylinder and component manufacturer in China, we specialize in supplying advanced solutions for the marine, industrial, and heavy equipment sectors. Our production facilities offer full in-house machining, assembly, and strict testing to ensure performance and reliability.

Whether you need custom marine hydraulic cylinders, hatch cover solutions, or other hydraulic components, we deliver products designed to withstand the toughest environments while keeping your operations efficient and cost-effective.