Hydraulic systems are the backbone of modern industry. They power everything from construction equipment to precision aerospace instruments. As a highly efficient form of power transmission, hydraulics combine fluid mechanics, mechanical engineering, materials science, and control theory into one integrated technology.

This article provides an in-depth look at hydraulic system principles, components, design guidelines, and maintenance practices. It is designed for engineers, technicians, and professionals who want a clear but technical overview.

What Is a Hydraulic System?

A hydraulic system is a power transmission method based on Pascal’s principle. This principle states that pressure applied to a confined fluid is transmitted equally in all directions. By using incompressible fluid such as hydraulic oil, these systems achieve force multiplication, precise control, and high power density.

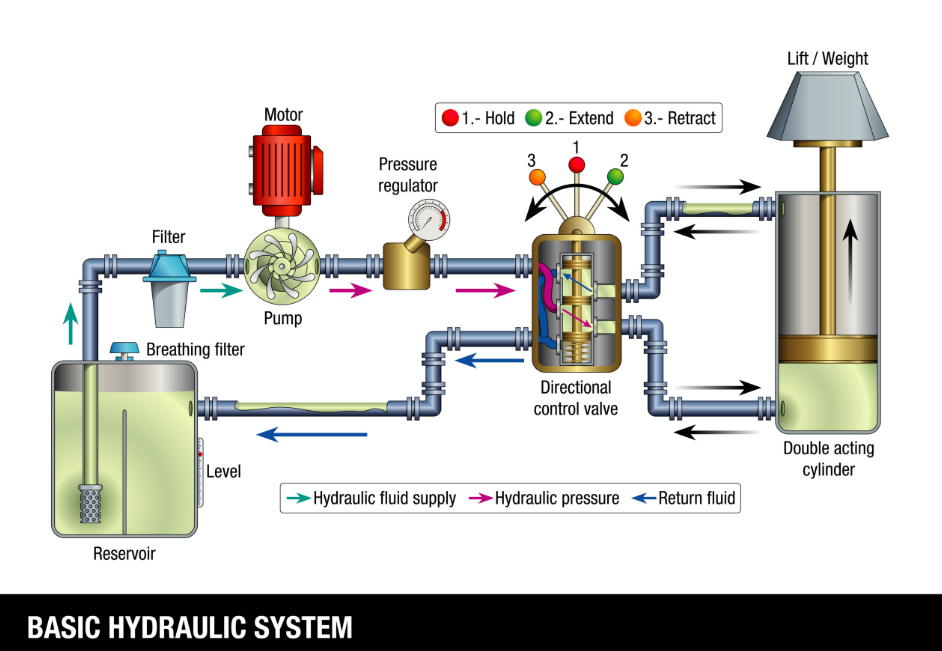

In practice, a hydraulic system consists of four main groups of components (ISO 1219: Fluid Power Symbols standard):

- Hydraulic pumps – supply power

- Hydraulic actuators – cylinders and motors that deliver movement

- Hydraulic valves – regulate flow and pressure

- Auxiliary components – tanks, filters, hoses, and coolers

Because of these advantages, hydraulics are used in presses, injection molding machines, excavators, aircraft, and many other applications.

Key Hydraulic Components and Their Functions

Hydraulic Pumps: The Heart of the System

Hydraulic pumps convert mechanical energy into fluid energy. There are three common types, each with different strengths:

| Pump Type | Pressure Range | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Gear Pump | ≤ 250 bar | Simple, low cost, durable | Less efficient, flow pulsation | Agricultural machinery, light-duty systems |

| Vane Pump | ≤ 300 bar | Quiet, stable flow, self-priming | Sensitive to contamination | Injection molding, mobile equipment |

| Piston Pump | ≥ 500 bar | High efficiency, compact, variable displacement | Higher cost, complex design | Aerospace, heavy presses, excavators |

As a result, pump selection depends on cost, required pressure, and desired efficiency.

Hydraulic Cylinders: Power Output Actuators

Hydraulic cylinders convert hydraulic energy into linear motion. Their performance depends on several design choices:

- Piston rods are typically made from alloy steel (38CrMoAlA), heat-treated, and chrome-plated. Coating thickness is usually 0.02–0.05 mm, while surface roughness is Ra ≤ 0.2 μm.

- Sealing systems often use multiple layers. Step seals handle high pressure, guide belts support alignment, and wipers prevent contamination.

- Mounting methods include eye-type, pivot-type, and flange-type supports. To ensure long service life, misalignment should not exceed 0.5°.

Because of these factors, proper design and installation are essential for reliable operation.

Hydraulic Valves: The Control Center

Valves regulate flow direction, pressure, and speed in hydraulic circuits. Different types serve different purposes:

- Proportional and servo valves offer precise control, with frequency responses above 100 Hz.

- Multi-section valves use load-sensing to distribute flow efficiently.

- Cartridge valves provide modular design, making systems flexible and reliable.

Therefore, valve selection should match the system’s complexity and control requirements.

Hydraulic System Design and Component Selection

Material Selection for Durability

Engineers must carefully select materials for hydraulic components:

- Housings: gray cast iron (low pressure), ductile cast iron (medium pressure), forged steel or aluminum (high pressure).

- Friction pairs: copper alloy–steel or advanced composites such as PEEK and PTFE.

Key Performance Parameters

When choosing hydraulic parts, attention should be given to:

- Efficiency – both volumetric and mechanical, especially under load.

- Temperature adaptability – cold-start performance and high-heat stability.

- Contamination resistance – measured using ISO 4406 codes.

- Service life – reliability predictions often use Weibull analysis.

System Integration Principles

System performance depends on correct matching of components:

- First, analyze load requirements including pressure, speed, and acceleration.

- Next, select pressure levels carefully; higher pressures reduce component size but increase cost.

- Finally, ensure stability. Use accumulators to absorb pressure spikes, and design pipelines to avoid resonance.

Hydraulic Maintenance and Reliability Practices

Contamination Control: The Key to Longevity

Over 70% of hydraulic failures are linked to oil contamination. For this reason, a multi-stage filtration strategy is critical:

- High-pressure filters protect sensitive components.

- Return filters maintain oil cleanliness.

- Breather filters block external particles.

In addition, oil analysis (particle counts, water, aging) and online monitoring systems help prevent failures before they occur.

Preventive Maintenance Strategies

A good maintenance plan combines three approaches:

- Time-based maintenance: scheduled replacement of seals and filters.

- Condition-based maintenance: adjustments triggered by monitoring data.

- Predictive maintenance: AI and big data forecast failures.

By combining these methods, downtime is reduced and reliability improves.

Fault Diagnosis in Hydraulic Systems

Engineers often use the method of observe, listen, inquire, and examine:

- Observe: oil color, leaks, or bubbles.

- Listen: abnormal noises or overheating.

- Inquire: collect details about operating conditions during the fault.

- Examine: check vibration, pressure, and temperature.

Furthermore, advanced diagnostic tools such as thermal imagers, ultrasonic detectors, and vibration analyzers help pinpoint problems quickly.

Application Examples of Hydraulic Systems

Hydraulic systems are used across many industries:

- Construction – excavators, cranes, and loaders rely on high-force cylinders.

- Manufacturing – presses and injection molding machines use hydraulics for precision.

- Aerospace – aircraft landing gear, brakes, and flight controls depend on high-pressure hydraulics.

- Renewable energy – wind turbines use hydraulics for pitch control and braking.

As a result, hydraulics remain indispensable in modern technology.

Conclusion

Hydraulic systems are essential in industrial automation, construction, aerospace, and manufacturing. By understanding their principles, components, and maintenance best practices, engineers can design and maintain systems that perform reliably over the long term.