As industries evolve, hydraulic transmission technology has become indispensable across global sectors—from construction and agriculture to mining and metallurgy. At the heart of these systems, hydraulic cylinders serve as critical actuators, delivering reliable linear and limited angular motion with unmatched efficiency.

Versatile Applications Across Industries

Our hydraulic cylinders power a wide range of machinery, ensuring robust performance in:

- Construction & Earthmoving – Excavators, bulldozers, compactors, and graders

- Material Handling – Forklifts, cranes, and conveyor systems

- Industrial & Heavy Equipment – Pile drivers, presses, and hydraulic lifts

- Agriculture, Mining & Automotive – Demanding environments where durability matters

Engineered for Reliability & Performance

A hydraulic transmission system consists of four core components: power units, actuators, control valves, and auxiliary elements. Among these, hydraulic cylinders stand out for their:

✔ Simple yet robust design – Minimizing complexity while maximizing uptime

✔ Precision motion control – Smooth linear and oscillating movement (<360°)

✔ Proven durability – Built to withstand high loads and harsh conditions

Hydraulic Cylinders: Core Components of Efficient Motion Control

As the driving force behind hydraulic systems, hydraulic cylinders are essential for converting fluid power into precise mechanical motion. Understanding their design and functionality helps in selecting the right solution for your application. Below, we outline the key aspects of hydraulic cylinders.

Types of Hydraulic Cylinders

Hydraulic cylinders are categorized based on different operational and structural characteristics:

- By Structure: Piston, plunger, telescopic, and rack-and-pinion designs

- By Motion: Linear reciprocating or rotary swing mechanisms

- By Action: Single-acting (pressure in one direction) or double-acting (bidirectional force)

- By Mounting: Tie-rod, clevis, flange, and trunnion configurations

- By Pressure Rating: Low, medium, medium-high, high, and ultra-high pressure variants

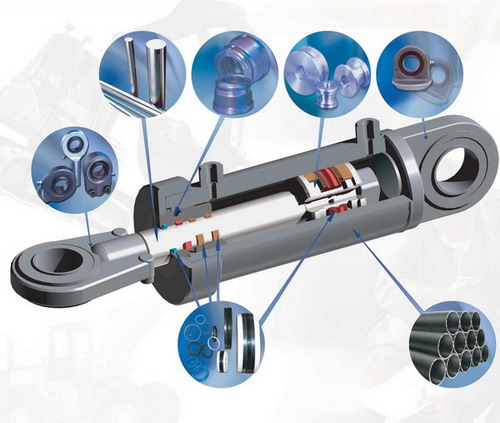

Hydraulic Cylinder Construction

Among the most common designs is the single-rod, double-acting piston hydraulic cylinder, valued for its simplicity and versatility. Its primary components include:

- Cylinder Barrel & End Caps – Housing the pressurized fluid

- Piston & Piston Rod Assembly – Transmitting force for linear motion

- Sealing System – Preventing leaks between high- and low-pressure zones

- Dust Guard – Protecting internal components from contamination

- Buffer & Exhaust Mechanisms – Ensuring smooth operation and preventing end-impact damage

Engineered for durability and efficiency, hydraulic cylinders ensure reliable performance in demanding environments. At JW Hydraulic, we specialize in high-quality hydraulic solutions tailored to your needs.

Discover the right hydraulic cylinder for your application—contact us today!