Hydraulic Cylinder Stepseals and Glyd Rings: A Complete Guide

In hydraulic cylinder engineering, reciprocating seals play a critical role. They directly influence service life, efficiency, and leakage control. Among the most widely used sealing solutions are Stepseals and Glyd Rings. Although they share design similarities—both being composite seals consisting of a PTFE-based glide ring combined with an elastomeric O-ring—their functional differences make them suitable for distinct applications.

This article explains their operating principles, design features, material options, and applications, helping engineers and procurement professionals choose the right sealing solution.

1. Functional Directionality

- Stepseal (Unidirectional): Designed to withstand fluid pressure from one side only. It is commonly used on piston rods where pressure consistently acts in a single direction.

- Glyd Ring (Bidirectional): Built for alternating pressure loads. One Glyd Ring can seal in both directions, which eliminates the need for two opposing seals.

📌General rule of thumb: Stepseals for rods, Glyd Rings for pistons.

2. Structural Design and Installation

| Seal Type | Geometric Profile | Installation Position | Functional Role |

|---|---|---|---|

| Stepseal | Stepped cross-section | Piston rod (shaft) | One-way dynamic sealing |

| Glyd Ring | Rectangular cross-section | Piston (bore) | Bi-directional dynamic sealing |

Both rely on a PTFE glide ring for low-friction sealing. In addition, an O-ring provides pre-load to maintain radial pressure and compensate for wear or deformation.

3. Operating Parameters

Stepseals and Glyd Rings perform well in demanding environments. For example:

- Pressure capability: up to 40 MPa

- Reciprocating speed: 4–5 m/s (depending on lubrication)

- Temperature range: −25°C to +200°C (based on elastomer selection)

- Medium compatibility: Hydraulic oils, eco-friendly fluids, and some water-based media

Therefore, they are suitable for both standard and heavy-duty hydraulic systems.

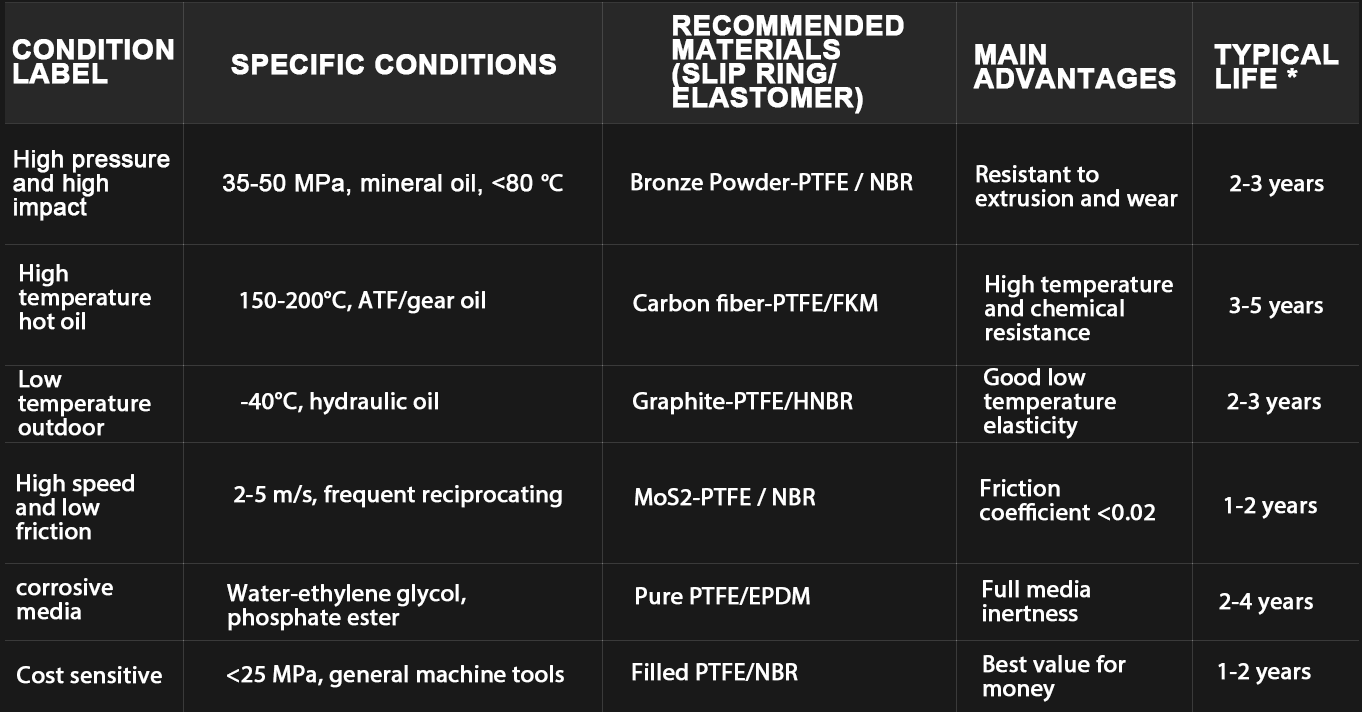

4. Material Engineering Considerations

Choosing the correct material is essential for long service life:

PTFE Glide Ring Compounds

- Virgin PTFE (standard)

- Bronze, carbon, MoS₂, graphene (for wear resistance)

- Glass fiber, PPS (to reduce cold flow)

- Modified PTFE, ETFE, PEEK (for corrosion resistance)

Elastomer O-Ring Options

- NBR: Cost-effective, suitable for mineral oils

- FKM: Excellent heat and chemical resistance

- HNBR, EPDM, FVMQ: Effective for low temperatures, synthetic fluids, or water-based media

As a result, the optimal material pairing is always application-specific, considering factors such as pressure, speed, and medium.

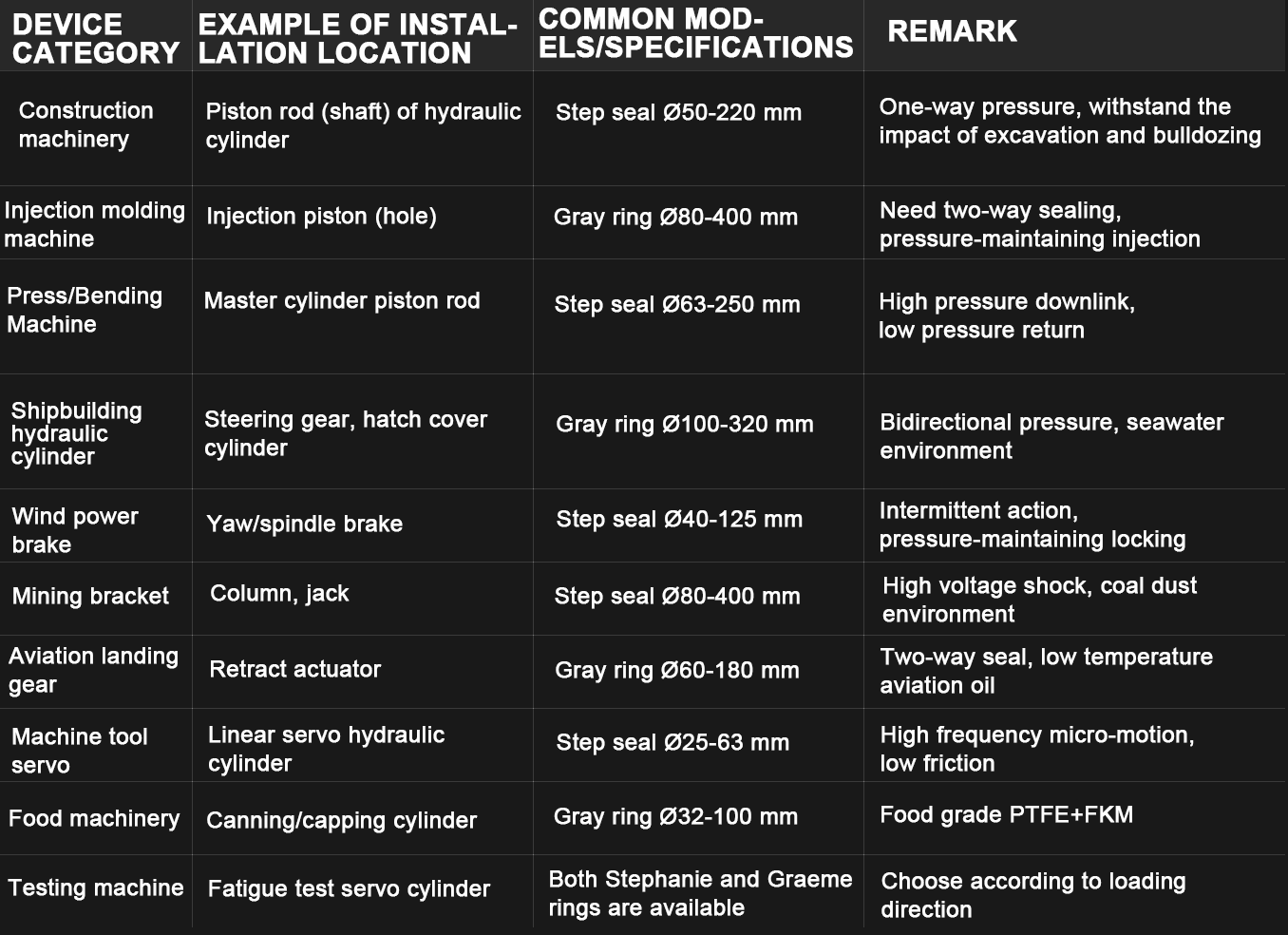

5. Industrial Applications

Stepseals and Glyd Rings are widely used in fluid power systems.

| Application Area | Typical Installation | Preferred Seal Type |

|---|---|---|

| Mobile hydraulics (excavators, loaders) | Piston rod | Stepseal |

| Heavy press machinery | Cylinder bore | Glyd Ring |

| Plastic injection molding machines | Piston | Glyd Ring |

| Marine/offshore hydraulics | Rod and bore | Combination use |

| Industrial hydraulic presses | Rod sealing | Stepseal |

In fact, studies show that over 90% of cylinder sealing systems rely on either Stepseals or Glyd Rings, proving their reliability and efficiency.

6. Conclusion

- Stepseal: Best for unidirectional rod sealing

- Glyd Ring: Ideal for bi-directional piston sealing

- Both: Durable PTFE + elastomer seals, resistant to pressure, wear, and temperature changes

By selecting the correct seal type and material, engineers can achieve leak-free operation, lower friction, and extended service life.

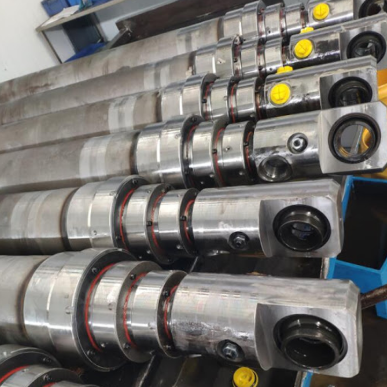

Our Expertise in Hydraulic Sealing Solutions

As a leading hydraulic cylinder and component manufacturer in China, we not only specialize in the production of cylinders but also provide a comprehensive range of hydraulic-related products and sealing solutions. Our product portfolio includes:

- Custom hydraulic cylinders (tie-rod, welded, mill-duty, telescopic, and more)

- Hydraulic components such as honed tubes, piston rods, cylinder barrels, and end caps

- Professional sealing elements including Stepseals, Glyd Rings, O-rings, wipers, and buffer seals

With advanced manufacturing facilities, strict quality control, and a dedicated engineering team, we ensure that every product meets international performance and durability standards. Whether you require standard replacements or custom-engineered sealing solutions, we can supply products tailored to your application requirements.

Our mission is to help clients worldwide achieve:

- Leak-free hydraulic performance

- Extended equipment service life

- Reduced downtime and maintenance costs

By choosing us as your partner, you gain not only a supplier but also a technical advisor for optimizing hydraulic cylinder performance.

JW Hydraulic

JW Hydraulic

JW Hydraulic