Hydraulic cylinders are critical components in industrial machinery, construction equipment, agricultural systems, and automation lines. They convert hydraulic energy into linear mechanical force, providing the power and precision required for lifting, pushing, pulling, and holding heavy loads.

This article provides a comprehensive overview of hydraulic cylinders, including their classification, structure, key parameters, common problems, and development trends.

1. Classification of Hydraulic Cylinders

Hydraulic cylinders can be categorized in multiple ways based on their design, function, and application environment:

- By Structure: piston type, plunger type, sleeve type, and rack-and-pinion type.

- By Motion: linear reciprocating type and rotary swing type.

- By Action: single-acting type (fluid acts on one side of the piston only) and double-acting type (fluid acts alternately on both sides).

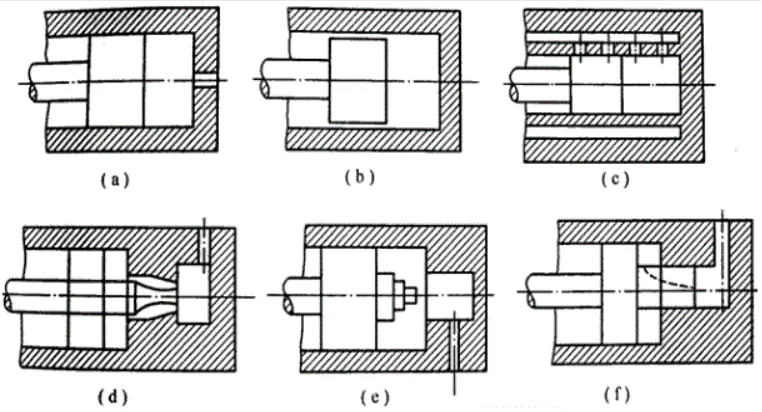

- By Mounting: tie-rod, earring, foot-mounted, and hinged shaft types.

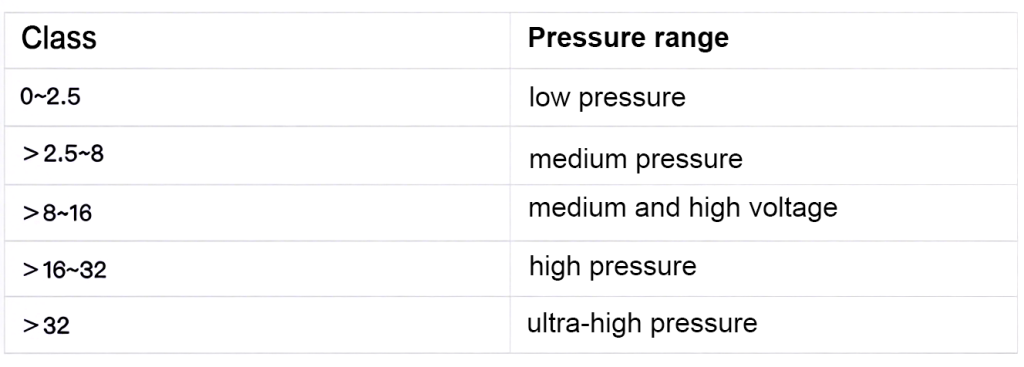

- By Pressure Level: low pressure, medium pressure, medium-high pressure, high pressure, and ultra-high pressure.

2. Hydraulic Cylinder Structure

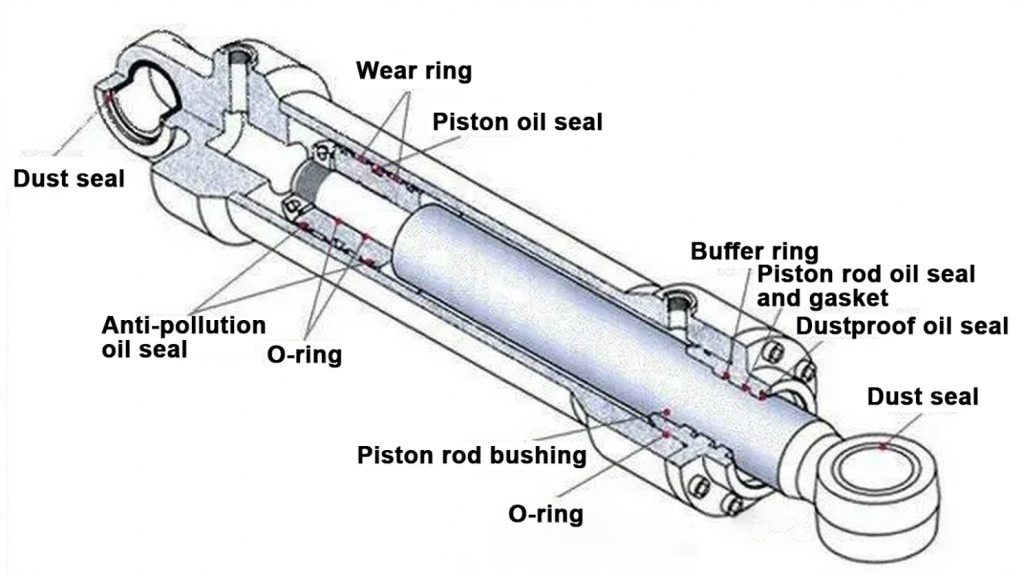

Among many types, the single-rod, double-acting piston cylinder is the most common. It consists of several key parts:

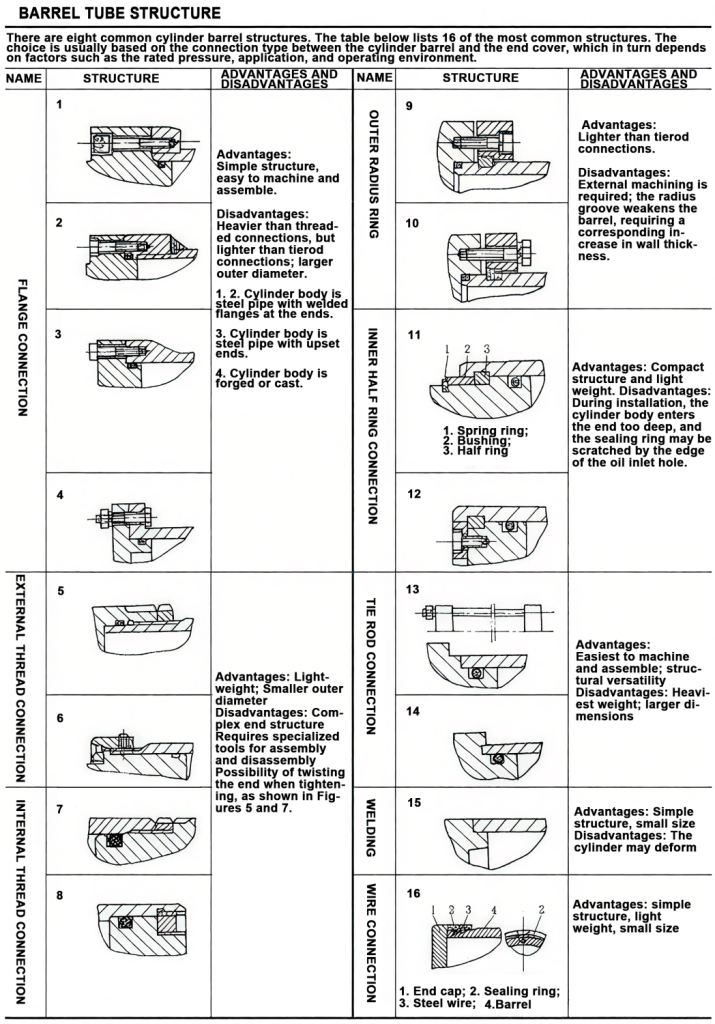

- Barrel Tube

- Forms the main chamber where hydraulic fluid acts on the piston.

- Different structural designs are available depending on the connection method with the end covers.

- Cylinder Head (End Caps)

- Installed at both ends of the barrel to form sealed chambers.

- Connected by welding, threading, bolting, or tie rods, depending on pressure rating and operating environment.

- Piston Rod

- The primary force-transmission element, usually made from medium-carbon steel.

- Requires high strength, straightness, roundness, and proper surface finish to reduce friction and wear.

- Piston

- Converts hydraulic energy into mechanical force.

- Connected to the piston rod using retaining rings, nuts, or sleeves.

- Materials range from ductile iron to carbon steel, depending on whether guide rings are used.

- Guide Sleeve

- Supports and aligns the piston rod.

- Contains seals and dust guards to prevent oil leakage and contamination.

- Materials include bronze, ductile iron, or advanced polymers such as PTFE for low friction and high wear resistance.

- Buffer Device

- Reduces impact and noise when the piston reaches the end of its stroke.

- Works by throttling oil flow, converting kinetic energy into heat dissipated by circulating oil.

- Sealing and Dust Protection

- Multiple seals are installed to prevent internal leakage and maintain pressure.

- Dust guards protect the cylinder from external contaminants such as dirt and moisture.

3. Main Parameters of Hydraulic Cylinders

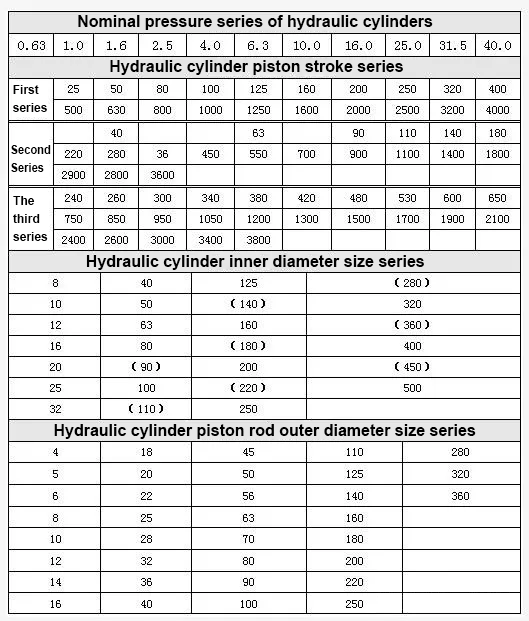

Design and selection of hydraulic cylinders depend on several performance parameters:

- Pressure (p = F/A): force applied per unit area. Higher pressure increases force output for a given piston size.

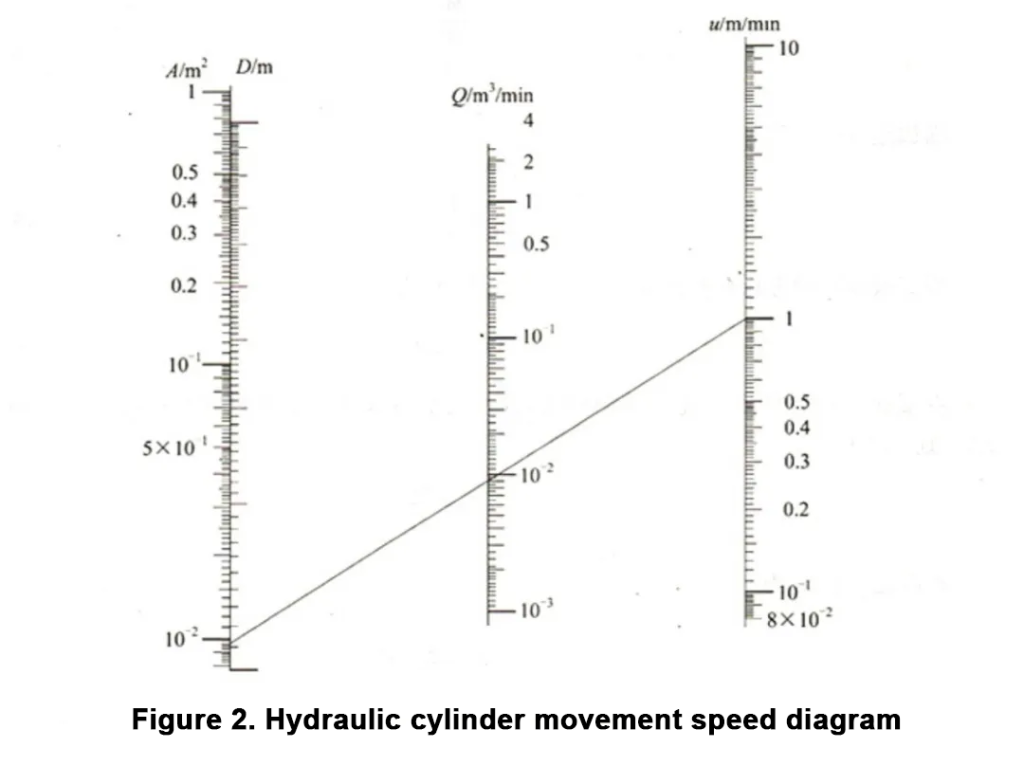

- Flow Rate (Q = V/t = vA): volume of hydraulic oil flowing per unit time, which determines piston speed.

- Piston Stroke: distance traveled during reciprocating motion. Must match application requirements while ensuring stability.

- Piston Speed (v = Q/A): typically 0.1–0.5 m/s depending on seal material and lubrication. Excessive speed can cause overheating and wear.

- Dimensions: cylinder diameter, piston rod diameter, and head size are calculated based on load, stroke, and mounting space.

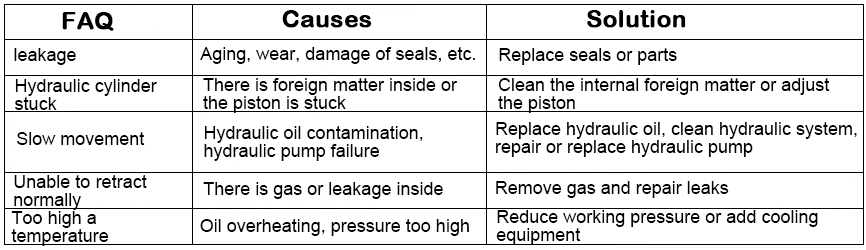

4. Common Problems and Maintenance

Like all mechanical components, hydraulic cylinders are subject to wear, fatigue, corrosion, and seal aging. Typical issues include:

- Oil leakage from worn seals.

- Surface damage to piston rods, causing seal failure.

- Internal scoring of the barrel due to contaminated hydraulic fluid.

- Unstable motion (creep or jerky movement) from trapped air or poor lubrication.

Preventive measures include:

- Regular inspection for leaks.

- Maintaining clean hydraulic oil.

- Monitoring piston rod condition.

- Following scheduled maintenance cycles to reduce downtime.

5. Development Trends of Hydraulic Cylinders

With the growth of hydraulic technology, modern hydraulic cylinders are evolving in several directions:

- Higher pressure and compact size – reducing overall weight and dimensions while increasing output power.

- New materials and lightweight design – using alloys and composites for better strength-to-weight ratio.

- Innovative structures – such as self-locking, telescopic, and composite hydraulic cylinders.

- High performance and modularity – easier installation, maintenance, and scalability.

- Energy efficiency and corrosion resistance – advanced sealing technology and optimized designs reduce leakage and extend service life.

- Intelligent and digitalized systems – integration of sensors for real-time monitoring, predictive maintenance, and Industry 4.0 compatibility.

Hydraulic cylinders are essential actuators in modern machinery, converting hydraulic pressure into linear mechanical force. By understanding their classification, structure, and parameters, as well as addressing common maintenance issues, industries can maximize efficiency and reliability. Looking forward, advancements in smart technology, materials, and energy efficiency will further enhance their role as indispensable components in industrial automation and heavy machinery.