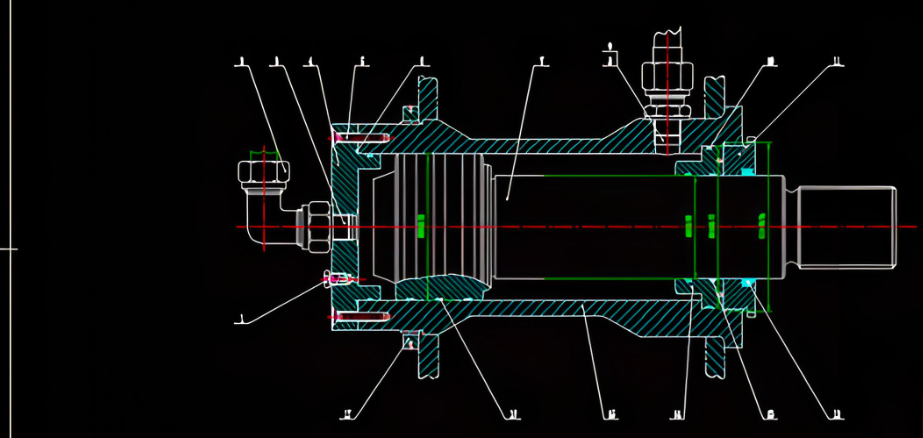

HYDRAULIC CYLINDER DESIGN

Key Steps

Determining Hydraulic Cylinder Dimensions

Piston Rod Stability Analysis: Conduct advanced buckling analysis to ensure rod stability under maximum compressive forces with safety factors.

Application-Specific Pressure Optimization: Customize working pressure parameters according to operational demands, distinguishing between different industrial grade requirements.

Calculate wall thickness and outer diameter: Calculate critical dimensions (bore size, rod diameter, structural thickness) through rigorous stress-strain modeling and material yield strength evaluations.

Stroke & Barrel Configuration: Align piston stroke with operational needs; set barrel length as stroke + piston width + end-cap allowances (≤20–30× bore diameter).

Structural Reliability Validation: Perform finite element analysis on end-cap thickness and guide sleeve geometry to guarantee zero deflection at full extension.

Framework

Structural Design of Hydraulic Cylinders

1. Connection Types

– Pressure-optimized flange connections

– Precision threaded interfaces

– inner/outer half-ring

2. Integral/Combined Designs

– Threaded, half-ring, or taper pin connections for load-specific durability.

3. Precision Components

– Head cap

– Guide sleeve

– Sealing/Dust proofing (O/V/Y/X-rings)

– Locking mechanisms

4. Contamination Defense

– Skeleton dust rings

– J-rubber seals, or felt rings to safeguard exposed rods.

5. Smart Sealing Solutions

– Pressure, temperature, speed, and sealing position dictate choice of O-rings, Y-lip seals, V-rings, or piston rings.

6. Advanced Cushioning Technology

– Tapered orifice impact absorption

– Variable-flow deceleration systems

– Mass-optimized energy management

7. Installation

– Dual exhaust valves (double-acting cylinders) positioned at cylinder’s highest points to purge trapped air during oil cycling.

8. Mounting Options

– Flange, trunnion, clevis, or long-bolt attachments for flexible integration.

9. Intelligent Port Configuration

– Inlet/outlet ports placed at cylinder ends or piston rod (fixed designs), prioritizing air expulsion via high-point placement.

JW Hydraulic

JW HYDRAULIC is a leading Asia-based manufacturer of hydraulic cylinders and precision components, delivers

custom-engineered solutions for maritime, offshore, metallurgy, mining, and construction sectors. Renowned for rigorous quality control, the products undergo extensive testing to meet stringent international certifications (ABS, Lloyd’s, DNV), ensuring exceptional durability and performance in the most demanding operating conditions. With a strong focus on innovation and engineering excellence, we continues to advance our expertise in hydraulic systems, providing high-performance, reliability-driven solutions for global industrial applications.

Contact Us

- Tel: +86 21 6266 6697

- Sales manager: jane.wang@jwgroup.cc

- Add: 2299, Xiangjiang Road, Shanghai 201804, China

Office Hour

- Monday – Friday: 9:00 AM – 6:00PM