Hydraulic Cylinder Components & Accessories

Our company supplies a complete range of hydraulic cylinder components and accessories.

All products are available in standard sizes and customized designs, ensuring the right fit for your application.

We recommend the best materials and processes based on your operating conditions, helping you achieve reliable performance and long service life.

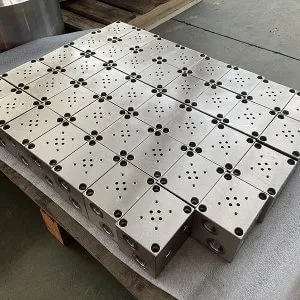

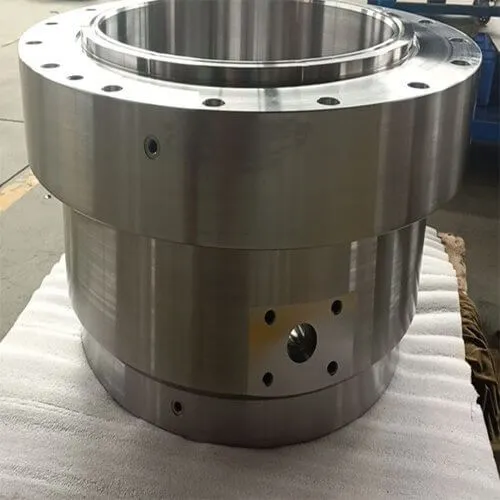

Product Gallery

Product Categories

| Product Item | Function & Application |

|---|---|

| Honed Tube | Pre-finished raw tube with accurate inner diameter and surface finish, ready for cylinder assembly |

| Cylinder Barrel | Finished barrel assembly with ports, mounting features, and honed inner bore for piston sealing |

| End Cap | Closes the non-rod end, provides port connections, and withstands hydraulic pressure loads |

| Head Cap | Guides and supports the piston rod, holds rod seals and wipers, ensures rod alignment |

| Piston Rod Blank | Base rod material before surface treatment |

| Hard Chrome Plated Piston Rod | Corrosion-resistant piston rod with high hardness (800–1000 HV), ready for assembly |

| Main Seal Kit | Complete kit ensuring leak-free operation |

| Piston Seal | Prevents internal fluid leakage between piston chambers |

| Rod Seal | Prevents fluid leakage along piston rod |

| Wiper Seal | Keeps contaminants out of the cylinder |

| Guide Band / Support Ring | Prevents metal-to-metal contact, provides rod/piston support |

| Static Seal Ring/O Ring | Provides versatile sealing for static or low-speed dynamic applications, ensuring leak-free performance under pressure |

| Flange | Provides rigid mounting interface |

| Clevis | Articulated mounting connection for dynamic loads |

| Pin Shaft | Connects clevis to equipment, withstands shear forces |

| Mounting Base | Fixed mounting interface for hydraulic cylinder |

| Cushioning / Buffer Device | Provides hydraulic buffering to ensure smooth deceleration at stroke ends, reduces impact, vibration, and protects equipment |

| Air Bleed Valve | Removes trapped air from cylinder or system |

| Exhaust Device | Releases residual air or excess pressure, ensuring safe cylinder operation and preventing overload |

| Rod Protective Cover | Protects piston rod from dust, dirt, and corrosion |

| Position Sensor | Non-contact rod position measurement for smart control |

| Sensor-Integrated Piston Rod | Enables real-time rod position monitoring |

| High-Temperature Seals | Designed for applications above 200°C |

| Corrosion-Resistant Plated Rod | Ideal for marine and chemical environments |

Key Features & Benefits

- Precision Manufacturing

- Honed tubes with H8–H9 tolerance and Ra 0.2–0.4 μm finish

- Chrome-plated rods with high hardness (800–1000 HV)

- End and head caps with CNC machining, port threading, and seal grooves

- Quality Assurance

- 100% pressure-tested end caps and head caps

- Dimensional inspection for all sealing surfaces

- Material certification available upon request

- Customization Service

- Standard and custom components available

- Built-to-print production based on drawings and specifications

- Engineering Support

- Expert recommendations on materials, seals, and finishes

- Technical consultation for application-specific requirements

JW Hydraulic

JW HYDRAULIC is a leading Asia-based manufacturer of hydraulic cylinders and precision components, delivers

custom-engineered solutions for maritime, offshore, metallurgy, mining, and construction sectors. Renowned for rigorous quality control, the products undergo extensive testing to meet stringent international certifications (ABS, Lloyd’s, DNV), ensuring exceptional durability and performance in the most demanding operating conditions. With a strong focus on innovation and engineering excellence, we continues to advance our expertise in hydraulic systems, providing high-performance, reliability-driven solutions for global industrial applications.

Contact Us

- Tel: +86 21 6266 6697

- Sales manager: jane.wang@jwgroup.cc

- Add: 2299, Xiangjiang Road, Shanghai 201804, China

Office Hour

- Monday – Friday: 9:00 AM – 6:00PM