Introduction

In industries where durability, wear resistance, and corrosion protection are critical, High Velocity Oxy-Fuel (HVOF) coating has become the go-to technology. From hydraulic cylinders to aerospace and offshore applications, HVOF coatings provide unmatched protection, extending service life and improving performance.

For companies aiming to boost the reliability of their hydraulic systems, understanding the benefits of HVOF is essential. This article explains what HVOF is, how it works, and why it is increasingly preferred over conventional surface treatments such as hard chrome plating.

What is HVOF Coating?

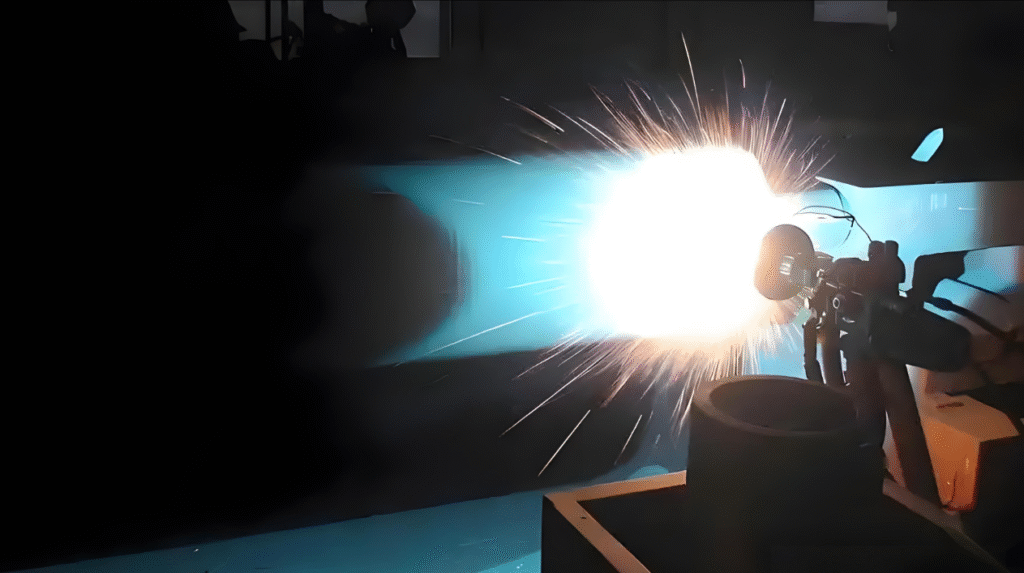

HVOF is an advanced thermal spray process designed to produce an exceptionally dense, strongly bonded coating. Using oxygen and fuel gases, fine carbide or alloy particles are accelerated at supersonic speeds and fused onto a component’s surface.

The result is a hard, wear-resistant, and corrosion-resistant coating that significantly enhances the durability of hydraulic cylinders, piston rods, and other high-stress components.

Key Benefits of HVOF Coating

- Smooth Surface Finish – Ensures low-friction movement, essential for hydraulic system efficiency.

- Outstanding Hardness – Typically exceeds 1,000 HV, surpassing traditional chrome plating.

- Superior Corrosion Protection – Guards against oxidation, rust, and aggressive environments such as saltwater.

- Extended Wear Life – Reduces friction and abrasion, helping parts last up to 3x longer.

- Eco-Friendly Solution – Unlike chrome plating, HVOF avoids hazardous chemicals such as hexavalent chromium.

HVOF vs. Hard Chrome Plating

For decades, hard chrome plating was the industry standard for hydraulic piston rods. However, performance limitations and increasing environmental restrictions are driving many sectors to adopt HVOF as a modern alternative.

| Property | HVOF Coating | Hard Chrome Plating |

|---|---|---|

| Hardness | 1,000 – 1,400 HV | 800 – 1,000 HV |

| Corrosion Resistance | Excellent (ideal for marine use) | Moderate (micro-cracks common) |

| Wear Resistance | Very High (2–3x longer life) | Moderate |

| Environmental Impact | Eco-friendly, no toxins | Contains toxic chromium |

| Long-Term Cost | Lower maintenance costs | Higher maintenance costs |

| Surface Finish | Smooth, low friction | May need extra finishing |

Conclusion: HVOF not only outperforms chrome in strength and longevity but also helps businesses reduce downtime, repair costs, and compliance risks.

Applications of HVOF-Coated Hydraulic Cylinders

HVOF is trusted across industries where components face extreme working conditions:

- Construction & Heavy Machinery – Protection against abrasive dirt and impact.

- Marine & Offshore – Long-lasting resistance to saltwater corrosion.

- Mining & Drilling – Durability under continuous wear and pressure.

- Agriculture – Defense against chemicals, fertilizers, and moisture.

- Aerospace & Defense – Reliable performance in high-temperature, high-stress environments.

Why Invest in HVOF for Hydraulic Cylinders?

Choosing HVOF-coated piston rods and components delivers measurable advantages:

- ✅ Longer Service Life – Equipment runs reliably with reduced wear.

- ✅ Reduced Maintenance & Downtime – Fewer replacements mean better productivity.

- ✅ Sustainability – Compliance with global environmental standards.

- ✅ Optimized Hydraulic Performance – Smooth, efficient operation with minimal friction.

Final Thoughts

As industries demand stronger, more sustainable solutions, HVOF coating is replacing hard chrome plating as the preferred surface technology for hydraulic cylinders. Businesses that adopt HVOF not only protect their equipment but also gain long-term cost savings, improved efficiency, and compliance with environmental regulations.

For companies relying on hydraulic systems, investing in HVOF-coated components is a forward-looking decision that delivers durability, reliability, and performance.

Why Choose HVOF for Your Hydraulic Cylinders?

If your business relies on hydraulic systems, investing in HVOF-coated hydraulic cylinder piston rods can offer multiple benefits:

- ✅ Extended Equipment Lifespan: Reduce wear and tear, minimizing maintenance costs.

- ✅ Reduced Downtime: Increase operational efficiency with durable components.

- ✅ Eco-Friendly Compliance: Avoid environmental regulations affecting chrome plating.

- ✅ Improved Performance: Achieve smoother, more efficient hydraulic operation.