When sourcing hydraulic components, one common question arises: Is a chrome plated rod the same as a piston rod?

Although they look similar, these two parts serve different purposes. Understanding their differences is essential for choosing reliable components and improving equipment life cycle.

What Is a Chrome Plated Rod?

A chrome plated rod is a precision-engineered steel bar designed for high wear resistance and smooth motion. It undergoes turning, heat treatment, grinding, and then hard chrome plating, typically with a thickness of 20–30 μm.

Technical Features:

Surface Roughness (Ra): 0.2–0.4 μm, ensuring excellent sliding performance

Hardness: HRC 58–65, which improves wear resistance and corrosion protection

Tolerances: h6/h7/f7 (ISO standard), enabling precise fits in guiding systems

Corrosion Resistance: 120+ hours in salt spray tests with standard plating (up to 500 hours with advanced coatings)

👉 Practical Example:

In packaging automation lines, chrome plated rods are used in linear guide systems. Their low friction surface reduces wear on seals and bearings, improving equipment uptime.

What Is a Piston Rod?

The piston rod is the core force-transmitting element in a hydraulic cylinder. It connects the piston to the external mechanism and is exposed to high loads, bending stress, and dynamic sealing conditions.

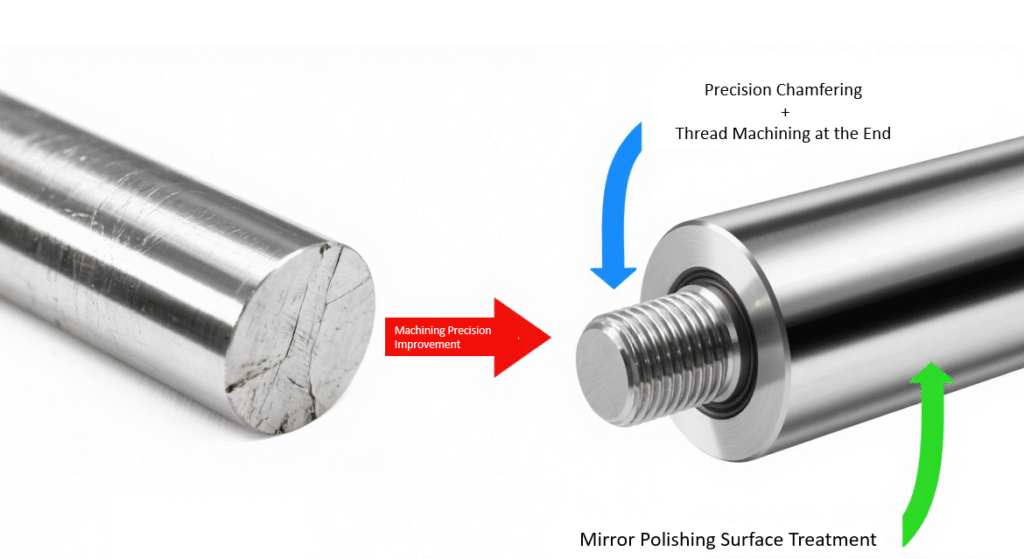

Unlike raw chrome rods, piston rods require further machining:

Threading and step machining for mounting

Induction hardening to increase fatigue resistance

End fittings (e.g., clevis, spherical eye, or flange) customized for equipment design

Technical Features:

Material: High-strength alloy steel such as CK45, 42CrMo4, or stainless steel for corrosive environments

Yield Strength: 600–800 MPa (42CrMo4 quenched and tempered)

Surface Treatment: Hard chrome plating or HVOF (High Velocity Oxy-Fuel) coating for advanced wear resistance

Fatigue Life: Typically designed for over 1 million load cycles under rated working pressure

👉 Practical Example:

In a hydraulic cylinder for an excavator boom, the piston rod must withstand repeated high-load cycles. A 100 mm diameter piston rod in such an application can transmit forces up to 780 kN at 100 bar operating pressure.

Chrome Plated Rod vs. Piston Rod: The Key Difference

| Feature | Chrome Plated Rod (Raw Material) | Piston Rod (Finished Component) |

|---|---|---|

| Function | Guide, support, sliding applications | Force transmission in cylinders |

| Processing | Grinding + Chrome plating | Machining + Threading + Chrome/HVOF |

| Applications | Linear guides, automation, machinery | Hydraulic & pneumatic cylinders |

| Customization | Limited (standard bars) | Fully customized for equipment |

Summary:

Chrome plated rod = starting material

Piston rod = engineered, application-ready component

Choosing the Right Component

If you need stock materials for machining, choose chrome plated rods.

If you need ready-to-install solutions, select custom piston rods designed for your machinery.

✅ Why Choose Us:

Chrome plated rods with 500+ hours salt spray resistance (optional advanced plating)

Piston rods with precision machining and fatigue-resistant design

Materials available in Ø 6 mm to Ø 300 mm with custom lengths up to 7 meters

Proven applications in construction machinery, marine hydraulics, steel mills, and energy projects

Final Thoughts

Both chrome plated rods and piston rods are essential for hydraulic systems, but they are not interchangeable. By understanding their roles and performance requirements, you can avoid costly downtime and ensure long-term reliability.

👉 Looking for premium chrome plated rods or piston rods for your hydraulic equipment? Contact our engineering team today to discuss custom solutions.