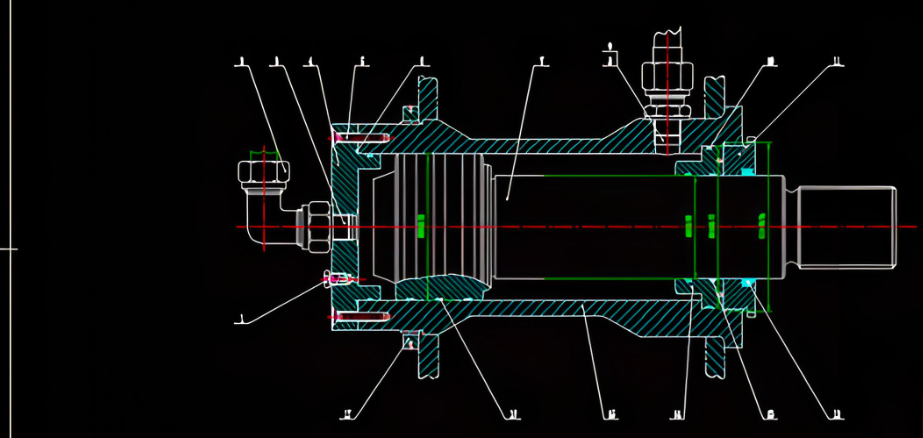

HYDRAULIC CYLINDER DESIGN

Determination of Main Dimensions of

Hydraulic Cylinders

Key Steps for Hydraulic Cylinder Dimensioning

Piston Rod Stability Analysis: Perform buckling resistance calculations under compressive loads to confirm compliance with safety factors.

Working Pressure Selection: Define operating pressure based on equipment type and application-specific load conditions (e.g., industrial vs. marine).

Core Dimensions Calculation: Determine cylinder bore, piston rod diameter, and wall thickness using load capacity formulas, pressure requirements, and material strength criteria.

Stroke & Barrel Length: Align piston stroke with operational needs; set barrel length as stroke + piston width + end-cap allowances (≤20–30× bore diameter).

Structural Integrity Checks: Validate cylinder head thickness and minimum guide sleeve length to prevent deflection and ensure stability during full extension.

Hydraulic Cylinder Structural Design Framework

After determining core dimensions, structural design focuses on critical components and functional systems:

- Connection Types: Flange, threaded, inner/outer half-ring (selected based on pressure, material, and operational demands).

- Integral/Combined Designs: Threaded, half-ring, or taper pin connections for load-specific durability.

- Components: Head cap, guide sleeve, sealing/dustproofing (O/V/Y/X-rings), and locking mechanisms.

- Dust Protection: Skeleton dust rings, J-rubber seals, or felt rings to safeguard exposed rods.

- Selection Criteria: Pressure, temperature, speed, and sealing position dictate choice of O-rings, Y-lip seals, V-rings, or piston rings.

- Purpose: Mitigate piston-end impact in high-speed/mass applications via integrated cushioning (e.g., tapered or variable orifice designs).

- Installation: Dual exhaust valves (double-acting cylinders) positioned at cylinder’s highest points to purge trapped air during oil cycling.

- Mounting Options: Flange, trunnion, clevis, or long-bolt attachments for flexible integration.

- Port Design: Inlet/outlet ports placed at cylinder ends or piston rod (fixed designs), prioritizing air expulsion via high-point placement.

JW CYLINDER, a leading Asia-based manufacturer of hydraulic cylinders and components, specializes in custom solutions for maritime, offshore, metallurgy, mining, and construction industries. Committed to excellence, their rigorously tested products meet international standards (ABS, Lloyd’s, DNV), ensuring reliability and superior quality in demanding environments. Driven by innovation, JW CYLINDER continues to expand its hydraulic market expertise while delivering performance-driven engineering solutions.

Contact Us

- +86 15021927761

- No. 2299, Xiangjiang Road, Shanghai 201804, China

- jane.wang@jwgroup.cc

Office Hour

- Monday – Sunday: 9:00 AM – 6:00PM